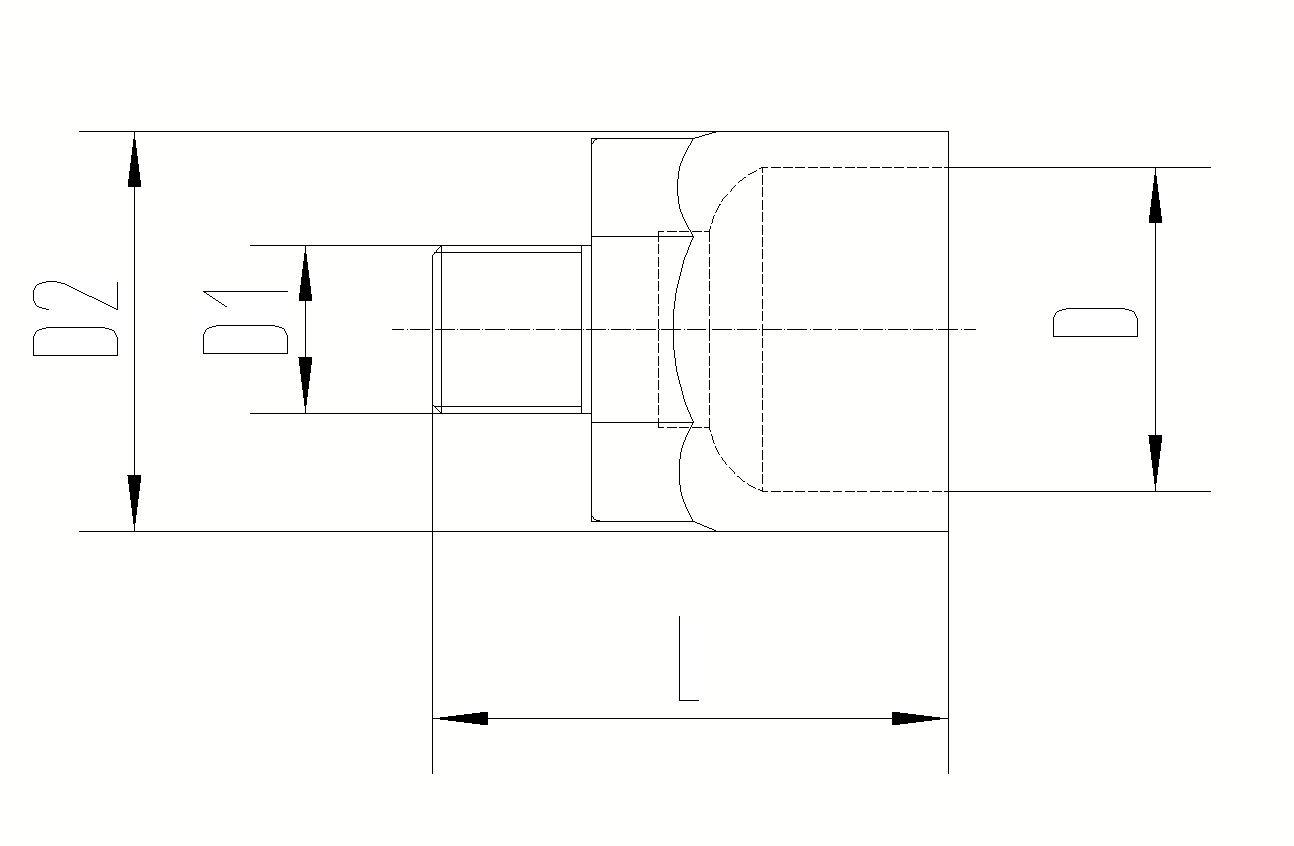

The purpose of the automotive steering tie rod ball joint is to have a tie rod with a ball joint housing. The ball joint of the steering spindle is placed inside the ball joint housing. The ball joint articulates with the edge of the shaft hole of the ball joint housing through the ball joint’s front-end ball joint seat. The needle rollers between the ball joint seat and the steering spindle are mounted in the groove on the inner hole surface of the ball joint seat.

The purpose of the automotive steering tie rod ball joint is to have a tie rod with a ball joint housing. The ball joint of the steering spindle is placed inside the ball joint housing. The ball joint articulates with the edge of the shaft hole of the ball joint housing through the ball joint’s front-end ball joint seat. The needle rollers between the ball joint seat and the steering spindle are mounted in the groove on the inner hole surface of the ball joint seat.

Components of the Automobile Steering Control System:

Material: Constructed from high-quality steel to ensure strength and durability, resulting in reliable performance and an extended lifespan.

Safety: Manufactured in accordance with IATF 16949 and ISO 9001 standards to ensure safety and reliability.

Design: The ball joint threads are manufactured using high-precision equipment, ensuring a precise fit with the tie rod threads, reducing play. Internally, imported rubber ball seats are used to achieve a maintenance-free function, enhancing the assembly’s lifespan.

Function: Transmits the steering input from the steering gearbox to the steering knuckle, achieving accurate and responsive steering. The tie rod connects the steering rack to the steering knuckle.

Load Capacity: Capable of withstanding high loads and forces, ensuring safe and reliable operation even under demanding driving conditions.

Lubrication: Pre-lubricated with high-quality automotive-specific lubricant or with the option for lubrication, ensuring smooth and consistent motion, reducing wear on the ball seats, and extending the assembly’s lifespan.

Installation: Easy to install, providing a secure and stable connection to the steering system.