Understanding the Importance of Tie Rod Ends in Vehicle Suspension Systems

The suspension system is one of the most vital components of any vehicle. It ensures that the vehicle rides smoothly and can handle the rigors of various terrains while maintaining driver comfort and control. A key part of the suspension system is the tie rod end, a relatively small yet incredibly important piece of hardware that connects the steering and suspension systems. Despite its size, the tie rod end plays an essential role in a vehicle’s stability, steering precision, and safety. In this article, we will explore what tie rod ends are, how they function, why they are essential to a vehicle’s suspension system, and the importance of regular maintenance to ensure they continue to perform effectively.

1. What Are Tie Rod Ends?

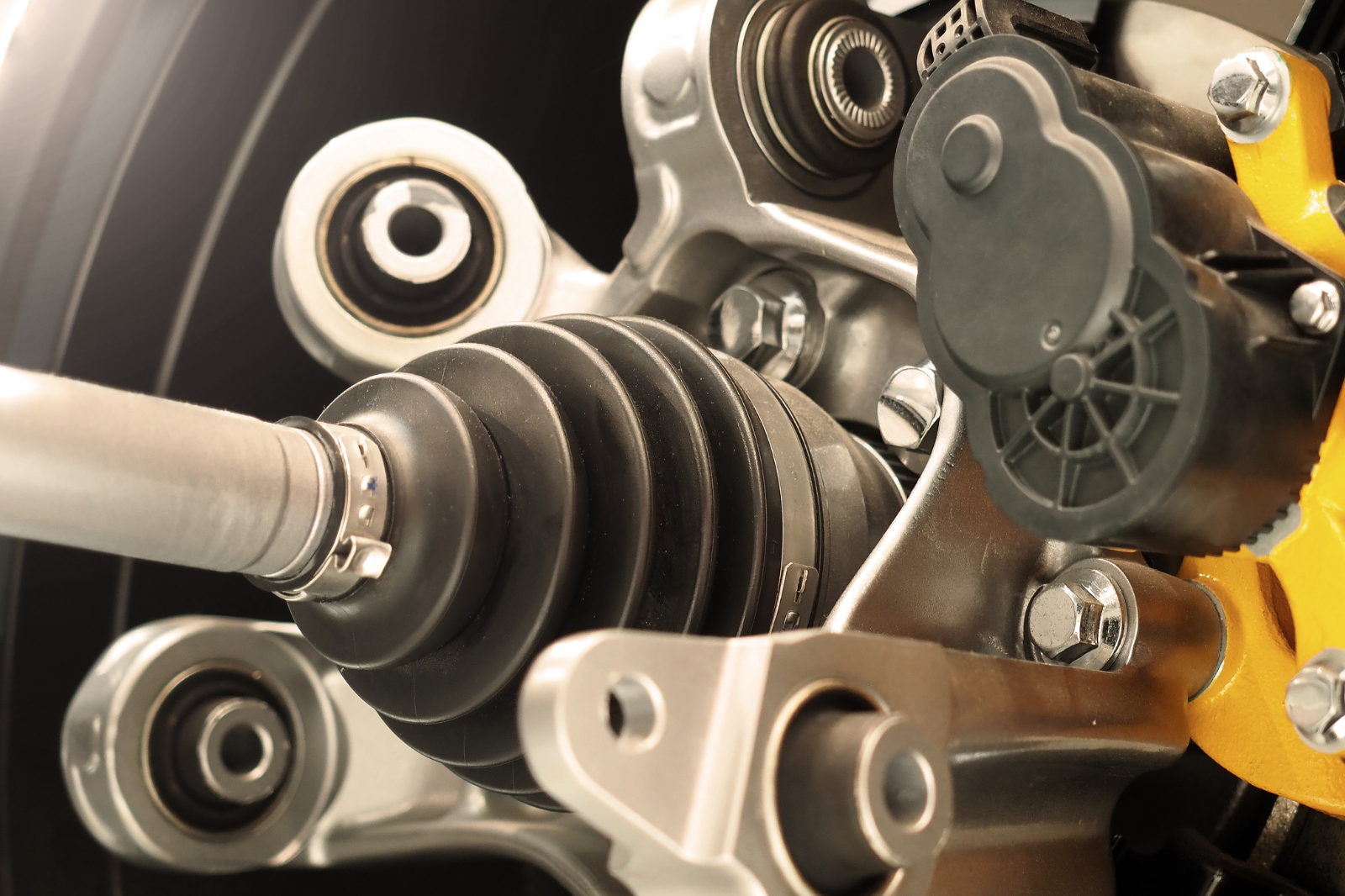

Tie rod ends are the final link in the chain that controls the movement of a vehicle’s wheels. They connect the steering rack (or steering gear) to the steering knuckle of each wheel. Essentially, tie rod ends are small joints that allow the wheels to pivot and turn as the driver turns the steering wheel. They consist of an outer and an inner component: the inner tie rod connects directly to the steering rack, while the outer tie rod end connects to the steering knuckle.

The tie rod end functions as a ball-and-socket joint, similar to the human hip. This design enables the tie rod end to move vertically and horizontally, allowing the wheels to turn while absorbing the up-and-down movement of the suspension. As a result, tie rod ends help keep the tires in proper alignment, ensuring optimal handling and a smooth driving experience.

2. History and Development of Tie Rod Ends

The invention of the tie rod dates back to the earliest forms of automobile steering systems. In the early 20th century, vehicle steering systems were quite rudimentary, often consisting of simple mechanical linkages that required a great deal of physical effort to operate. As cars became more advanced, manufacturers began to experiment with systems that could offer greater precision and control, particularly as vehicle speeds increased and safety became more of a concern.

In the 1930s and 1940s, with the development of rack-and-pinion steering, the tie rod end became a critical component of steering systems. Rack-and-pinion steering systems use a rack that moves laterally, turning the tie rods, which then pivot the wheels. This design became popular for its simplicity, durability, and improved handling.

Today, nearly all modern cars utilize some form of tie rod ends in their suspension and steering systems. With advancements in materials and manufacturing techniques, tie rod ends are now made from high-strength alloys and are designed to withstand extreme conditions. Despite their durability, however, they are still prone to wear and tear, which makes maintenance crucial.

3. The Role of Tie Rod Ends in Steering Systems

In a typical rack-and-pinion steering system, the driver’s input on the steering wheel is transferred through the steering column to the steering rack. The steering rack moves side-to-side, pulling or pushing the tie rods, which then rotate the wheels. Tie rod ends are what connect the tie rods to the wheels, and they are essential for translating the steering rack’s motion into wheel movement.

Without properly functioning tie rod ends, a vehicle would be virtually impossible to steer. As the primary link between the steering gear and the wheels, they ensure that the vehicle responds precisely to the driver’s inputs. Over time, however, the ball-and-socket joint within the tie rod end can wear out, causing play in the steering system, which leads to imprecise steering and decreased control.

3.1 Types of Steering Systems Using Tie Rod Ends

Most modern vehicles use rack-and-pinion steering systems, but tie rod ends are also used in other steering systems, such as recirculating ball steering, which is commonly found in trucks and heavy-duty vehicles. In this system, the tie rod ends connect the steering gear to the wheels in a similar fashion, though the method of transferring the driver’s input differs.

- Rack-and-pinion steering: This system is lighter and offers more precise control, making it the preferred choice for most passenger cars.

- Recirculating ball steering: Often found in larger vehicles like trucks and SUVs, this system is heavier and more robust but lacks the precise control of rack-and-pinion steering.

Despite the differences in steering system design, the role of the tie rod end remains consistent—allowing the wheels to pivot in response to the driver’s steering input.

4. The Impact of Tie Rod Ends on Vehicle Alignment

One of the most critical functions of tie rod ends is their influence on wheel alignment, particularly toe alignment. The toe refers to the angle at which the wheels point relative to the centerline of the vehicle. If the wheels are aligned correctly, the tires will roll straight down the road. However, if the toe alignment is off, even slightly, it can lead to uneven tire wear, poor handling, and decreased fuel efficiency.

4.1 What is Toe Alignment?

Toe alignment refers to whether the front of the tires are closer together or farther apart than the rear of the tires. It can be categorized into three types:

- Toe-in: The front of the tires point inward toward the centerline of the vehicle.

- Toe-out: The front of the tires point outward, away from the centerline.

- Neutral toe: The tires point directly forward, offering the best combination of stability and tire wear.

The tie rod ends play a crucial role in maintaining this alignment. If a tie rod end becomes worn or damaged, the alignment will shift, leading to steering issues and premature tire wear. Regular inspections and alignment checks are necessary to ensure the tie rod ends remain in good working condition.

5. Contribution to Suspension Stability

Although tie rod ends are primarily associated with steering, they also contribute to the stability of a vehicle’s suspension system. A vehicle’s suspension system is designed to keep the tires in contact with the road surface for optimal traction and handling. Tie rod ends help by ensuring the wheels remain properly aligned, minimizing the risk of wheel wobble or instability during driving.

When a tie rod end wears out, it can cause the vehicle to pull to one side or result in a noticeable “play” in the steering wheel, meaning that the vehicle may not respond immediately to steering inputs. This can compromise both handling and braking, making the vehicle more difficult to control, particularly at higher speeds or in emergency situations.

6. Signs of Tie Rod End Wear

Like any mechanical component, tie rod ends are subject to wear over time due to road conditions, exposure to debris, and the general stresses of driving. Common signs of worn tie rod ends include:

- Steering wheel vibrations: Particularly noticeable at higher speeds, vibrations may indicate that the tie rod end is no longer maintaining a firm connection between the steering rack and the wheel.

- Uneven tire wear: Misalignment caused by failing tie rod ends can cause one side of the tire to wear down more quickly than the other.

- Loose or shaky steering: A worn tie rod end will create excessive play in the steering system, making it feel less responsive or “loose.”

- Clunking or knocking noises: When turning the wheel or driving over bumps, worn tie rod ends may produce clunking or knocking sounds.

Ignoring these symptoms can lead to a failure of the tie rod ends, which could result in a dangerous loss of steering control. Regular inspections by a certified mechanic can help detect wear and prevent major issues before they arise.

7. Maintenance and Safety of Tie Rod Ends

Maintaining the tie rod ends is crucial for both the safety and performance of the vehicle. Tie rod ends are subject to wear and tear, particularly in regions with rough roads or harsh weather conditions. Regular inspections should be conducted, especially if the vehicle shows any symptoms of tie rod end wear. During routine maintenance, mechanics typically check for play or looseness in the tie rods, ensuring that the steering system remains tight and responsive.

In many cases, replacing a tie rod end is relatively inexpensive compared to the potential damage that can result from neglecting this critical component. Failing to address worn tie rod ends can lead to misalignment, uneven tire wear, and even catastrophic failure, potentially resulting in a serious accident.

8. Choosing Quality Tie Rod Ends for Durability and Performance

When replacing or maintaining tie rod ends, choosing high-quality parts is essential for ensuring longevity and optimal performance. Juye Parts, a leading manufacturer of automotive steering and transmission components, provides high-quality tie rod ends designed for durability and precision. With a focus on advanced materials and engineering, Juye Parts offers a wide range of components that meet the demanding standards of modern vehicles.

Juye Parts’ tie rod ends are built to withstand the rigors of everyday driving, including rough road conditions, heavy loads, and high-speed operation. Their products undergo rigorous testing to ensure they meet or exceed OEM specifications, providing drivers with confidence in their vehicle’s handling and safety. Whether for passenger cars, trucks, or SUVs, Juye Parts offers reliable and durable solutions for all types of vehicles.

9. Conclusion

In conclusion, tie rod ends are a crucial component of a vehicle’s steering and suspension systems, ensuring accurate steering, proper wheel alignment, and overall vehicle stability. Regular maintenance and prompt replacement of worn tie rod ends are essential for maintaining safe driving conditions and optimal vehicle performance. By choosing high-quality parts from trusted manufacturers like Juye Parts, drivers can ensure their vehicles remain responsive and safe on the road.

Maintaining your vehicle’s tie rod ends and ensuring that they are in good working condition is a fundamental aspect of vehicle safety and performance, emphasizing the importance of choosing quality components and regular inspections.

Juye is a leading manufacturer of steering system components, renowned for innovation and quality. With over 20 years experience and certifications like ISO9000 and IATF16949, We offer efficient production, technical excellence, and eco-friendly practices. Our goal is to provide tailored solutions for Automobile steering and transmission, enhance user experience, and contribute to sustainable development. Contact us now!

Leave a Reply