How to Choose the Right Stabilizer Link Manufacturer ?

Choosing the right stabilizer link manufacturer is crucial for ensuring the long-term safety, performance, and reliability of a vehicle’s suspension system. Stabilizer links, also known as sway bar links, are essential components in modern suspension setups, helping maintain vehicle stability and control during cornering and other maneuvers. Selecting a manufacturer that offers durable, high-quality parts is essential for both vehicle owners and automotive businesses. This guide will walk you through the key considerations for choosing a stabilizer link manufacturer, giving you the insights you need to make an informed decision.

1. Evaluate the Manufacturer’s Reputation

One of the first steps in selecting the right stabilizer link manufacturer is to assess their reputation in the industry. Reputation reflects not only the quality of the products but also the reliability of the company as a business partner.

Researching Online Reviews and Feedback

Start by researching online reviews and testimonials from customers. Many automotive parts suppliers and manufacturers are reviewed by individual buyers, mechanics, or automotive businesses. Look for feedback on industry-specific forums, social media platforms, and automotive review sites to gather real-world user experiences. Reading through these reviews can offer valuable insights into the manufacturer’s product quality, customer service, and overall reliability.

Industry Certifications and Standards

A good manufacturer should hold relevant certifications that demonstrate compliance with industry standards. Certifications like ISO 9001, which confirms a company’s commitment to quality management systems, or IATF 16949, a global standard specifically for the automotive sector, can indicate that a manufacturer follows strict quality protocols. These certifications are especially important for customers who prioritize long-lasting and reliable parts.

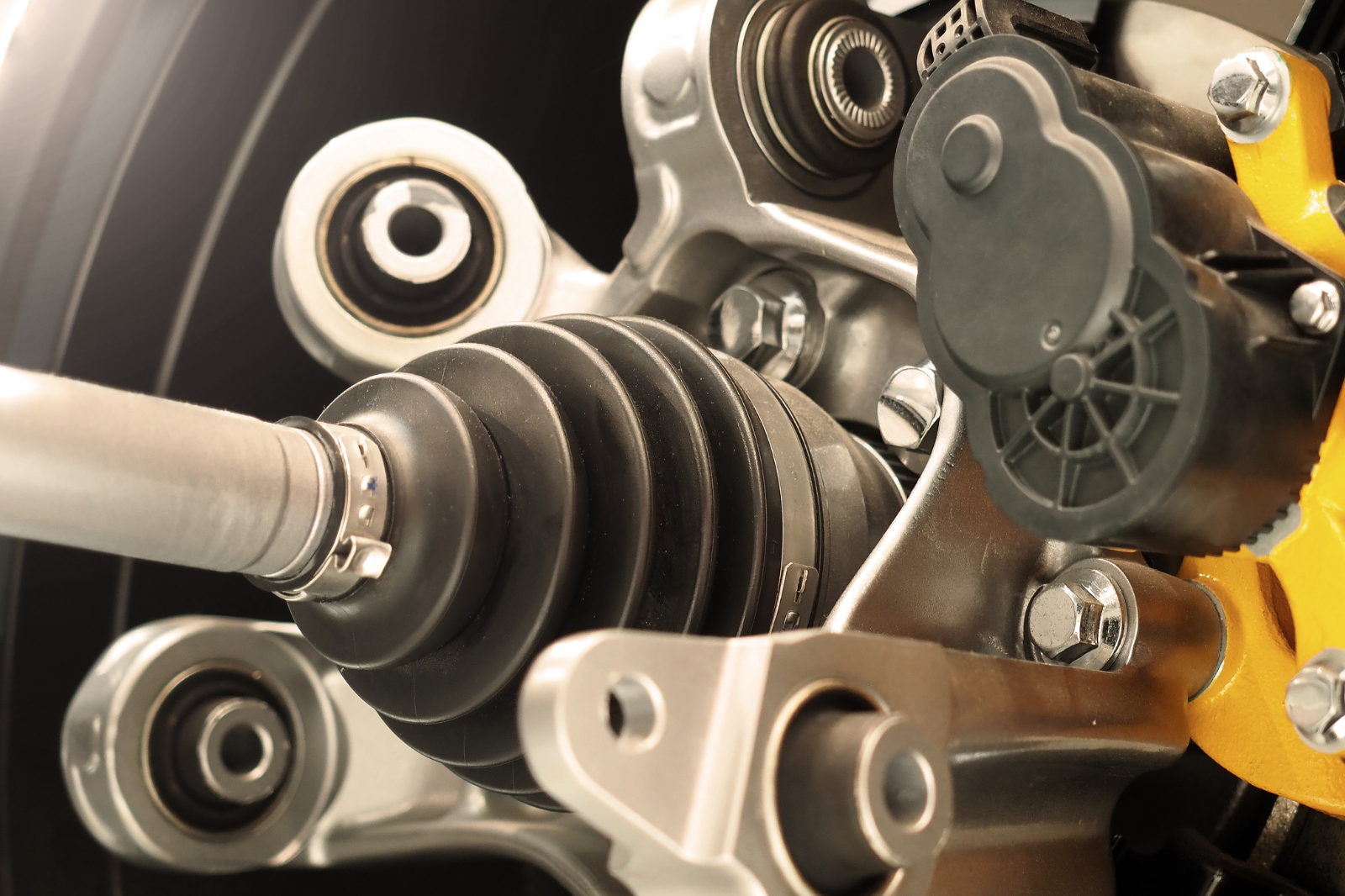

2. Assess Product Quality

Ensuring that the stabilizer links are built from premium materials and with attention to detail is paramount. Poor-quality stabilizer links can wear out quickly, resulting in vehicle instability and the need for frequent replacements.

Material Selection

Stabilizer links are typically constructed from materials like steel, alloy, or composite materials. The choice of material plays a key role in determining durability, weight, and overall performance. Steel is commonly used for its strength and durability, but manufacturers that offer advanced composite materials may provide additional benefits such as weight savings and corrosion resistance.

Manufacturing Precision

High-quality stabilizer links should be made with precision to ensure they fit correctly into the vehicle’s suspension system. An improperly fitting link can lead to increased wear and tear, noise, and even safety risks. Modern manufacturers often use advanced techniques like CNC (Computer Numerical Control) machining to ensure exact dimensions and tolerances for every part produced.

Testing and Durability Standards

Look for manufacturers that perform rigorous testing on their stabilizer links, including fatigue testing, corrosion resistance tests, and load-bearing assessments. Parts should meet or exceed OEM (Original Equipment Manufacturer) specifications, meaning they match the quality of the parts originally installed in the vehicle.

OEM vs. Aftermarket Parts

Another key consideration is whether to go with OEM parts or aftermarket parts. OEM stabilizer links are designed to match the exact specifications of the vehicle, ensuring a perfect fit and performance. Aftermarket parts, on the other hand, may offer enhancements like improved durability or additional features, but they can vary in quality depending on the manufacturer. Therefore, if you’re opting for aftermarket parts, it’s essential to choose a trusted and reputable manufacturer.

3. Manufacturing Process

The manufacturing process is a crucial element that affects both the quality of the stabilizer links and the reliability of the manufacturer’s production capabilities.

Technology and Automation

Manufacturers that invest in modern technology and automation tend to produce higher-quality parts. Automated production lines, robotic welding, and laser cutting can enhance consistency, reduce defects, and improve overall efficiency. Manufacturers using CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) systems can better manage tolerances and create parts that perform optimally under various conditions.

Quality Control and Inspection

The best manufacturers have stringent quality control processes in place at every stage of production. Look for manufacturers that employ Six Sigma or Lean Manufacturing principles, as these methodologies focus on reducing waste and defects while improving efficiency. Parts should undergo rigorous inspections before they leave the factory to ensure that they meet the required standards.

Environmental Sustainability

In recent years, sustainability has become an increasingly important factor in the automotive industry. Manufacturers that follow environmentally friendly practices, such as using recycled materials or reducing waste, can offer an added value to businesses looking to align with sustainable practices. Check if the manufacturer complies with environmental standards like ISO 14001, which certifies that they manage their environmental impact effectively.

4. Supply Chain and Delivery

An efficient and reliable supply chain is critical, especially if you are a business or automotive repair shop that depends on timely deliveries to serve customers.

Inventory Management

Choose manufacturers that have robust inventory management systems. This ensures they can fulfill your orders on time, whether you need a small or large quantity of stabilizer links. Just-In-Time (JIT) delivery systems can be particularly beneficial for businesses that do not want to stock large quantities but need quick access to parts.

Global Distribution Network

If your business operates internationally, it’s essential to choose a manufacturer with a global distribution network or partnerships with reliable shipping providers. Manufacturers with established export processes can navigate international shipping complexities more effectively and deliver products on time.

Lead Times and Availability

The manufacturer’s ability to meet your specific demand within a reasonable time frame is also a key factor. Some manufacturers might offer faster turnaround times if they keep a large inventory of stabilizer links, while others may have longer lead times if they manufacture parts to order.

5. Price vs. Value

While price is an important consideration, it should not be the sole determining factor. High-quality stabilizer links may come at a higher price, but they often provide better durability, performance, and long-term value.

Cost-Effectiveness

Evaluate the total cost of ownership, including the frequency of replacement and potential labor costs. Low-cost stabilizer links may save you money upfront but could lead to frequent replacements or vehicle issues in the long run. High-quality parts, although more expensive initially, may provide a longer service life and reduce the need for repairs.

Warranties and Guarantees

Manufacturers that offer robust warranties on their products provide peace of mind. These warranties not only protect against manufacturing defects but also signal the manufacturer’s confidence in their product’s durability and performance.

6. Introduction to Juye Parts

When searching for a reputable manufacturer, Juye Parts (www.juyeparts.com) stands out as a leading producer of high-quality automotive steering and transmission components. With years of industry experience, Juye Parts offers a broad range of components, including stabilizer links, steering arms, control arms, and ball joints, all built to meet stringent performance and safety standards.

Their commitment to excellence is reflected in their use of advanced manufacturing technologies and rigorous quality control processes, ensuring that every part meets or exceeds OEM specifications. Juye Parts also prioritizes customer satisfaction by offering flexible delivery options and excellent after-sales support, making them a trusted partner for businesses and repair shops worldwide.

For more details, visit their official website.

7. Customization and Flexibility

If your needs are specific, it’s important to find manufacturers that offer customization options. Whether it’s a particular material, design, or size, some manufacturers are flexible and able to adapt to your specifications. For instance, Juye Parts offers customized solutions for clients requiring unique steering or transmission components. This flexibility can be particularly useful for businesses that need parts for specialty or older vehicle models that may not be readily available in standard catalogs.

Leave a Reply