Everything You Need to Know About Ball Joint OEM & ODM

Ball joints are pivotal components within a vehicle’s suspension system, playing a crucial role in ensuring smooth and stable driving. Their primary function is to connect the steering knuckles to the control arms, facilitating the vehicle’s suspension movement and steering. In this comprehensive guide, we will explore everything you need to know about ball joints, including the differences between OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) options, and provide detailed insights into their selection, installation, and maintenance. Additionally, we’ll introduce a notable manufacturer in the automotive parts industry, Juyeparts, known for its expertise in steering and driveline components.

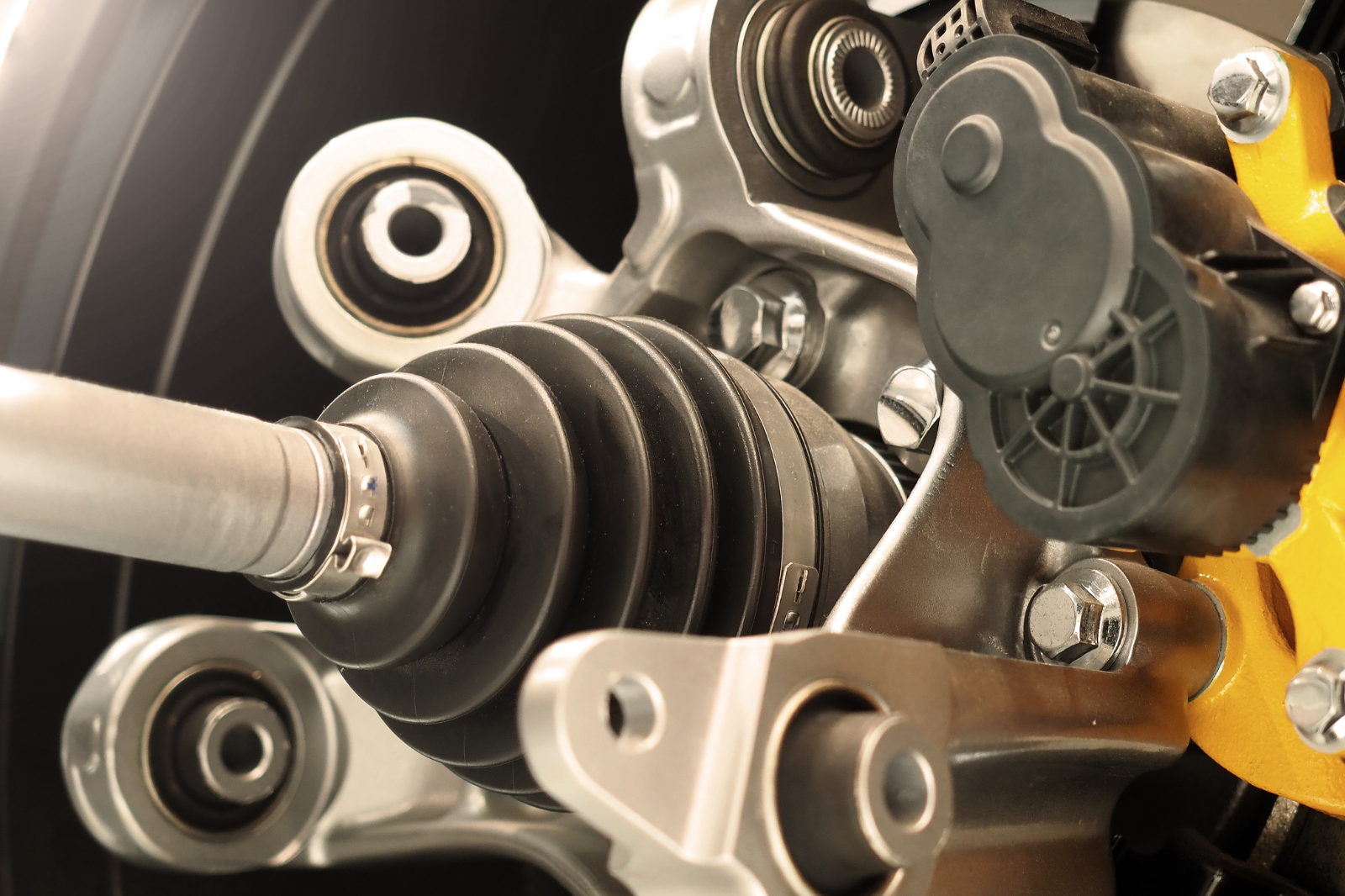

1. What is a Ball Joint?

A ball joint is a crucial element of a vehicle’s suspension system that allows for smooth articulation between the steering knuckle and the control arm. It operates as a pivot point, enabling the vehicle’s suspension system to move and absorb shocks while maintaining alignment and control. Ball joints come in two primary types:

Upper Ball Joints: These are positioned on the upper part of the suspension system and connect the control arm to the steering knuckle. They support the vehicle’s weight and contribute to the suspension’s overall stability.

Lower Ball Joints: Located on the lower part of the suspension system, these joints connect the steering knuckle to the lower control arm. They play a significant role in steering control and impact absorption.

2. OEM vs. ODM Ball Joints

Understanding the differences between OEM and ODM ball joints is essential for making an informed decision. Each type has distinct characteristics and benefits:

2.1 OEM Ball Joints

OEM (Original Equipment Manufacturer) ball joints are produced by the same company that manufactured the original components for the vehicle. These parts are designed to meet the exact specifications and standards set by the vehicle’s manufacturer. Here’s what you need to know about OEM ball joints:

Precision and Compatibility: OEM ball joints are made to match the original equipment perfectly, ensuring precise fitment and compatibility with your vehicle. This reduces the risk of issues related to misalignment or improper fit.

Quality Assurance: OEM parts are subject to rigorous quality control processes and adhere to high manufacturing standards. This guarantees that the parts will perform reliably and maintain the vehicle’s intended safety and performance levels.

Warranty and Support: Purchasing OEM ball joints typically comes with manufacturer warranties and support, providing added peace of mind and protection against defects.

Cost Considerations: OEM ball joints are often more expensive compared to aftermarket options. The higher cost reflects the quality and assurance of the original parts.

2.2 ODM Ball Joints

ODM (Original Design Manufacturer) ball joints are custom-designed components produced by manufacturers based on specific requirements provided by the buyer. Here’s an overview of ODM ball joints:

Customization: ODM manufacturers can design ball joints to meet unique specifications, which is beneficial for custom applications or specific performance requirements. This flexibility allows for tailored solutions that might not be available through OEM options.

Cost-Effectiveness: ODM parts can be more affordable, especially for large orders or when specific design features are required. The cost savings can be significant, particularly if customization is needed.

Quality Variability: The quality of ODM ball joints can vary depending on the manufacturer’s standards and processes. It is crucial to select a reputable ODM manufacturer with robust quality control to ensure the parts meet required specifications.

Design and Engineering: ODM ball joints may not always match the exact design of OEM parts. Ensure that the custom design adheres to industry standards and provides the required functionality.

3. Key Considerations for Choosing Ball Joints

When selecting ball joints for your vehicle, several factors should be taken into account to ensure optimal performance and safety:

3.1 Material and Construction

The material and construction of ball joints significantly impact their durability and performance. High-strength steel and other durable alloys are commonly used to ensure that the ball joints can withstand the stresses and strains of the suspension system. Key considerations include:

Material Strength: Choose ball joints made from high-quality materials that offer strength and resistance to wear and tear. The material should be able to handle the forces exerted during driving and ensure long-term reliability.

Construction Quality: Examine the construction of the ball joints to ensure they are manufactured to high standards. Look for features such as reinforced housings, precision-engineered sockets, and high-quality bearings.

3.2 Design and Engineering

The design and engineering of ball joints affect their performance and compatibility. Consider the following:

OEM Design: OEM ball joints are designed to match the original specifications perfectly, ensuring seamless integration with the vehicle’s suspension system.

ODM Customization: ODM ball joints offer customization options, which can be useful for specific applications or performance enhancements. Ensure that the custom design adheres to industry standards and provides the required functionality.

Compatibility: Verify that the ball joints are compatible with your vehicle’s make and model. This is especially important for ODM parts, where customization may lead to variations in fitment.

3.3 Quality Control

Quality control is critical for ensuring the reliability and performance of ball joints. When choosing between OEM and ODM parts:

OEM Quality Control: OEM parts generally come with guaranteed quality due to strict manufacturing and testing processes. This ensures that the parts meet the required safety and performance standards.

ODM Quality Assurance: For ODM ball joints, verify the manufacturer’s quality control practices. Look for certifications and standards that indicate rigorous testing and quality assurance.

3.4 Cost

Cost is an important consideration when choosing ball joints. Evaluate the cost in relation to the benefits and requirements:

OEM Costs: OEM ball joints are usually more expensive due to their guaranteed fit and quality. The higher cost may be justified for vehicles that require exact replacements or where manufacturer warranties are a priority.

ODM Costs: ODM ball joints can offer cost savings, particularly for custom applications or bulk orders. However, ensure that the cost savings do not compromise the quality and performance of the parts.

4. Finding a Manufacturer

Choosing the right manufacturer is crucial for obtaining high-quality ball joints. Here’s how to find reliable suppliers:

4.1 OEM Manufacturers

Major Suppliers: Well-known automotive part suppliers such as Bosch, Delphi, and Denso are reputable for producing OEM ball joints. You can contact these manufacturers directly or through authorized distributors to obtain OEM parts.

Authorized Dealers: Many vehicle manufacturers have authorized dealers and service centers that offer OEM parts. These dealers can provide genuine ball joints and ensure proper fitment.

4.2 ODM Manufacturers

Finding ODM Suppliers: Numerous ODM manufacturers specialize in automotive components, including ball joints. Websites like Alibaba or industry-specific directories can help you locate potential suppliers.

Evaluating ODM Partners: When selecting an ODM manufacturer, consider factors such as design capabilities, production capacity, and track record. Request samples or references to assess the quality and reliability of their products.

5. Introduction to Juyeparts

When it comes to sourcing high-quality steering and driveline components, Juyeparts is a notable player in the industry. Juyeparts specializes in manufacturing a wide range of automotive parts, including ball joints, steering components, and driveline parts. Their expertise lies in producing reliable, high-performance parts that meet the rigorous demands of modern vehicles.

Key Features of Juyeparts:

Expertise in Steering and Driveline Components: Juyeparts has extensive experience in designing and manufacturing components critical to vehicle steering and driveline systems. This expertise ensures that their products offer superior performance and durability.

Quality Assurance: Juyeparts adheres to stringent quality control standards, ensuring that all parts are manufactured to high specifications. Their commitment to quality is reflected in their robust testing processes and certifications.

Customization Options: For those requiring specific design features or custom solutions, Juyeparts offers ODM services that allow for tailored solutions to meet unique requirements.

Global Reach: With a focus on international markets, Juyeparts provides high-quality components to a global customer base, supporting various automotive applications worldwide.

For more information about their products and services, visit Juyeparts.

6. Installation and Maintenance

Proper installation and maintenance of ball joints are essential for ensuring their longevity and performance. Here’s what you need to know:

6.1 Installation

Professional Installation: Ball joints should be installed by a professional mechanic or technician. Proper installation is crucial to ensure that the ball joints are correctly fitted and aligned, preventing potential issues.

Alignment: After installation, it is important to have the vehicle’s alignment checked and adjusted. Proper alignment ensures that the ball joints function correctly and helps prevent premature wear.

6.2 Maintenance

Regular Inspections: Regularly inspect the ball joints for signs of wear or damage. Look for symptoms such as clunking noises, steering instability, or uneven tire wear.

Lubrication: Ball joints often require lubrication to maintain smooth operation. Follow the manufacturer’s recommendations for lubrication intervals and use the appropriate grease.

Replacement: If ball joints show signs of significant wear or damage, they should be replaced promptly. Worn ball joints can affect vehicle handling and safety.

7. Data Trends and Market Insights

The automotive parts industry, including ball joints, is experiencing notable trends driven by advancements in technology and changing market demands:

Growth in Automotive Aftermarket: The global automotive aftermarket industry is projected to grow significantly, with ball joints and suspension parts being key segments. According to a report by Market Research Future, the automotive aftermarket is expected to reach a market value of USD 560 billion by 2025, driven by increasing vehicle ownership and demand for replacement parts.

Advancements in Manufacturing: Technological advancements in manufacturing processes, such as precision machining and material science, are enhancing the performance and durability of ball joints. Innovations in manufacturing are contributing to the development of more reliable and cost-effective components.

Rising Demand for Custom Solutions: There is a growing demand for customized automotive parts, including ball joints, driven by specific performance requirements and aftermarket modifications. ODM manufacturers are increasingly focusing on providing tailored solutions to meet these needs.

Sustainability Trends: The automotive industry is placing greater emphasis on sustainability, with a focus on reducing environmental impact. This trend includes the development of eco-friendly manufacturing processes and materials for automotive parts.

For more detailed market insights, you can explore industry reports and studies from sources like Grand View Research and Frost & Sullivan.

Conclusion

Ball joints are essential components of a vehicle’s suspension system, and choosing the right type—whether OEM or ODM—can significantly impact vehicle performance and safety. Understanding the differences between OEM and ODM options, along with considering factors such as material, design, and quality control, is crucial for making an informed decision. Additionally, exploring reputable manufacturers like Juyeparts can provide access to high-quality steering and driveline components. By staying informed about industry trends and ensuring proper installation and maintenance, you can ensure the longevity and reliability of your vehicle’s ball joints.

Leave a Reply