10 Tips for Working with a Suspension Ball Joint Manufacturer

ntroduction

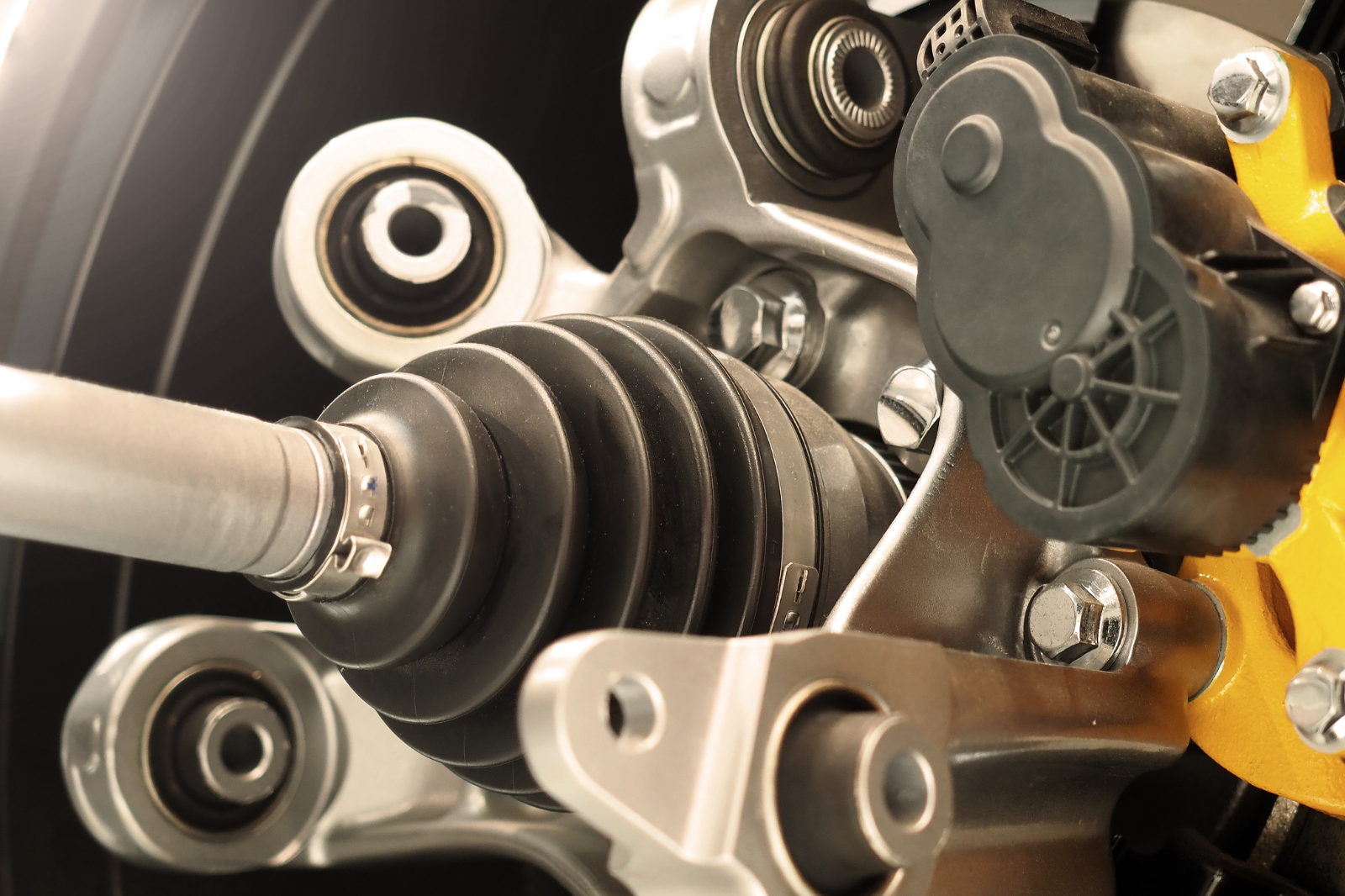

When working with a suspension ball joint manufacturer, ensuring a productive and successful partnership is key to delivering quality products that meet performance standards. Suspension ball joints are vital in automotive applications, allowing movement and flexibility between the control arms and the steering knuckles, providing a smooth ride and steering precision.

For example, the global automotive suspension market is expected to grow at a CAGR of 4.5% from 2021 to 2026, driven by rising vehicle production and the increasing demand for comfort and performance (Mordor Intelligence). This growth highlights the importance of choosing the right manufacturer to meet the industry’s evolving needs.

Let’s explore 10 tips that can help you work effectively with a suspension ball joint manufacturer and ensure success.

1. Clearly Define Your Requirements

Detailed Specification

Clear communication of specifications is critical when collaborating with a suspension ball joint manufacturer. According to a 2023 industry report, companies that provided detailed technical specifications during the initial stages of the project experienced a 20% decrease in project delays (PwC).

When outlining your needs, be sure to include dimensions, materials, and performance expectations. Providing detailed drawings, material standards, and CAD models allows the manufacturer to understand the full scope of your project, ensuring that the final product will meet your requirements.

Collaborate with Engineers

Working closely with the manufacturer’s engineering team, such as those at Juyeparts, can help bridge the gap between conceptual designs and practical production. Their technical expertise can be invaluable in troubleshooting potential issues during the development phase.

2. Research and Select a Reputable Manufacturer

Background Check

Selecting a reputable manufacturer is crucial to the success of your project. According to data from the Automotive Aftermarket Suppliers Association (AASA), 72% of companies that vetted their suppliers through thorough research reported higher satisfaction with product quality (AASA).

When selecting a manufacturer, look for a company that has a proven track record, like Juyeparts, which specializes in producing high-quality suspension ball joints and other automotive parts. Juyeparts stands out due to its advanced manufacturing techniques and rigorous quality control measures.

Facility Visits

Whenever possible, visit the manufacturing facility to evaluate the company’s production capabilities and quality control processes. This not only builds trust but also ensures that the manufacturer can meet your project’s specifications and deadlines. Companies that engage in site visits tend to have a 30% reduction in production errors (Manufacturing.net).

3. Request Samples and Prototypes

Evaluation

Before committing to large-scale production, request prototypes or samples. This is an essential step to evaluate whether the ball joints meet your application’s functional and quality standards. For example, a study conducted in 2022 found that 68% of companies using prototypes caught potential design flaws before full-scale production, resulting in fewer defects and rework (Forbes).

At Juyeparts, manufacturers offer sample testing to ensure that the product performs well in real-world applications. Their ball joints undergo rigorous testing for durability, corrosion resistance, and performance under extreme conditions.

Feedback and Adjustments

Once you’ve tested the sample, provide detailed feedback. This iterative process allows for adjustments in design, materials, or manufacturing methods to refine the final product.

4. Understand the Manufacturing Process

Process Transparency

Understanding the manufacturer’s production process gives you insight into their capabilities and the quality of the final product. Transparency is key—ask questions about the types of materials used, the methods of production (such as casting or forging), and the quality control measures they follow.

In 2021, manufacturers that emphasized transparency in their production process reported a 25% increase in client retention, as clear communication fosters trust and long-term relationships (McKinsey).

5. Discuss Quality Control Procedures

Quality Assurance

Quality control should be a top priority in any manufacturing partnership. According to McKinsey & Company, companies that implement stringent quality control measures during production see a 50% reduction in product defects (McKinsey).

At Juyeparts, strict quality control measures are part of their manufacturing process. Their suspension ball joints undergo thorough inspection and testing at multiple stages of production, ensuring they meet industry standards like ISO 9001.

6. Negotiate Terms and Pricing

Contract Negotiation

Upfront negotiations on terms such as pricing, payment schedules, and delivery timelines are essential to avoid any future misunderstandings. A survey conducted by Deloitte found that clear contract terms result in a 35% improvement in supplier relationship management (Deloitte).

By negotiating well, companies can secure favorable terms that align with their budgets and project timelines. When working with Juyeparts, be sure to discuss any custom order requirements, as well as potential discounts for bulk orders.

7. Establish Clear Communication Channels

Point of Contact

Having a single point of contact ensures consistent and clear communication, which can significantly reduce errors and delays. According to a 2020 report by Harvard Business Review, companies with effective communication strategies are 29% more likely to meet their project deadlines (Harvard Business Review).

8. Monitor Production and Quality Assurance

Production Oversight

Keeping a close eye on the production process helps to identify potential issues early. In fact, businesses that maintain regular oversight of production report a 40% decrease in costly errors (IndustryWeek).

Working with a manufacturer like Juyeparts gives you access to detailed progress reports and consistent updates on production timelines, ensuring transparency.

9. Understand Warranty and Support Policies

Warranty Terms

Having a clear understanding of the manufacturer’s warranty and support policies is crucial. A 2023 industry analysis found that 60% of companies that fully understood warranty terms were able to resolve defects faster, reducing downtime by 15% (Statista).

At Juyeparts, you can expect detailed warranty policies that cover product defects and customer support services to address any concerns.

10. Build a Long-Term Relationship

Partnership Building

Fostering a long-term relationship with your manufacturer can result in better terms and improved collaboration. A study by CIPS (Chartered Institute of Procurement & Supply) found that businesses that maintained long-term relationships with suppliers saw a 25% improvement in cost savings (CIPS).

By following these expanded tips, supported by industry data and research, you can ensure a successful partnership with a suspension ball joint manufacturer like Juyeparts, known for their quality products and excellent service.

Leave a Reply