The Function and Damage Symptoms of Ball Joints

Ball joints are crucial components of the vehicle’s chassis system, connecting the suspension system to the vehicle body, ensuring smooth driving and stable steering. Their role not only affects driving comfort but also directly impacts driving safety. This article will explore the function of ball joints, symptoms of damage, maintenance and inspection methods, and key points and procedures for additional chassis system components. This information is essential for any ball joint manufacturer, ball joint supplier, or ball joint company aiming to provide high-quality components to their customers.

Function of Ball Joints

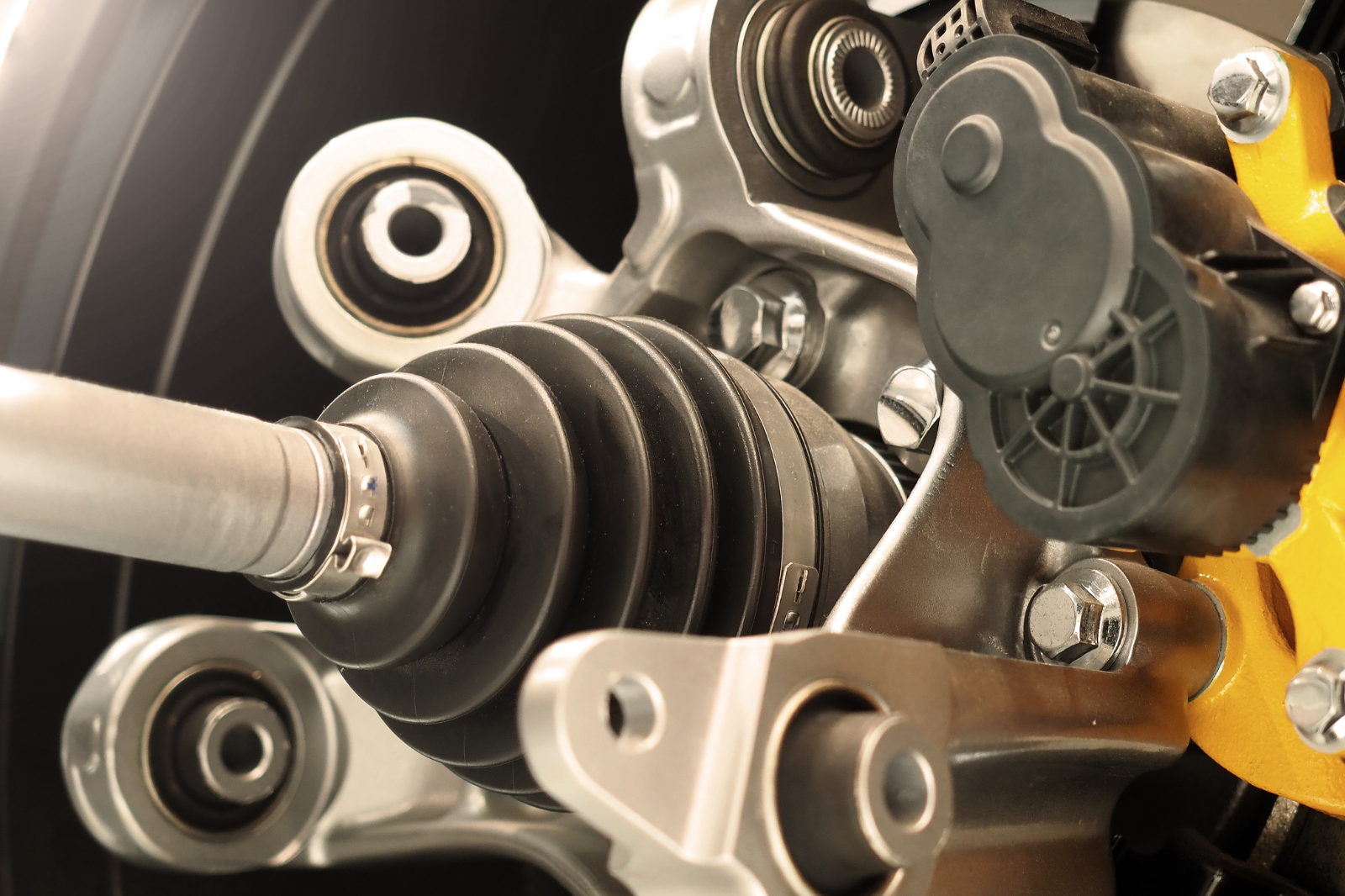

Every car has multiple ball joints, including rubber sleeves and stabilizer bar ball joints. These ball joints can be categorized into two types based on their location and function:

Upper Ball Joints: These primarily bear horizontal or lateral torque, not the vehicle’s weight. Their main role is to provide tensile strength and maintain the stability of the suspension system. Upper ball joints are crucial during steering, as they bear the lateral forces to ensure smooth turning.

Lower Ball Joints: These support the vehicle’s weight and are known as load-bearing ball joints. They bear and support the vehicle during driving, absorbing the weight and impact from the road.

The design of ball joints allows them to rotate freely in multiple directions, providing the necessary flexibility for the suspension system. They enable the suspension system to maintain contact between the wheels and the ground while absorbing road shocks, thus enhancing vehicle comfort and handling performance. A reliable ball joint manufacturer ensures these components meet stringent quality standards to perform effectively.

Symptoms of Ball Joint Damage

Ball joints, due to bearing forces from different directions and constant movement, are prone to various damages. Common symptoms of damage include:

Oil Leakage: Ball joints contain lubricating oil or grease to ensure smooth sliding between metal components. If the seal is damaged, the lubricating oil leaks out, leading to insufficient lubrication and accelerated wear. Oil leakage not only affects lubrication but can also contaminate internal parts, speeding up damage.

Breakage and Cracking: The rubber sleeves of ball joints may break or crack due to aging or external forces over time, leading to lubricating oil leakage and affecting the normal operation of the ball joints. Damaged rubber sleeves allow dust and moisture to enter the ball joint, exacerbating wear.

Deformation: Steering ball joints can deform under excessive tensile force, affecting the vehicle’s steering performance and making handling unstable. Deformed ball joints may fail to accurately transmit steering force, making driving hazardous.

For a ball joint manufacturer or supplier, understanding these symptoms is crucial to improving product durability and reliability.

Causes of Ball Joint Damage

Several factors can cause ball joint damage, including:

Environmental Factors: Rain, dirt, and salt can corrode and wear out ball joints, especially in cold climates where salt’s corrosive effect is more pronounced.

Driving Habits: Aggressive driving habits like frequent sharp turns and sudden stops increase the load on ball joints, shortening their lifespan.

Road Conditions: Driving on rough, uneven roads increases wear on ball joints, as the suspension system constantly adjusts to the changing surface.

Improper Maintenance: Lack of regular inspection and maintenance, such as not adding lubricating oil on time, leads to insufficient lubrication and accelerates wear.

Maintenance and Inspection of Ball Joints

Regular inspection and maintenance of ball joints are necessary to ensure the vehicle’s normal operation and safety. Key points for maintenance and inspection include:

Regularly Check Seal Condition: Inspect rubber sleeves for integrity and oil leakage. Visual inspection or professional tools can be used to detect seal integrity.

Check for Looseness: Manually shake the ball joint to detect any looseness or abnormal gaps. Loose ball joints produce noise during driving, affecting handling performance.

Regular Lubrication: For lubricable ball joints, add lubricating oil or grease regularly to maintain normal operation. Lubrication reduces friction, extending the ball joint’s lifespan.

Auditory Inspection: Listen for unusual noises from the suspension system during driving, especially when turning or driving on uneven roads, and inspect the ball joints promptly if any noise is detected.

Professional Inspection: During routine maintenance, have professional technicians use specialized equipment to check the ball joint’s condition, ensuring it is in optimal working condition.

By adhering to these maintenance practices, a ball joint supplier or ball joint company can enhance the longevity and performance of their products.

Key Points and Procedures for Additional Chassis System Components

When maintaining and repairing the chassis system, follow these key steps:

Inspection and Recording: Thoroughly inspect the status of all chassis system components, including ball joints, stabilizer bars, and rubber sleeves, and record any damaged or replaceable parts. Pay special attention to the seal integrity, lubrication status, and wear degree of ball joints.

Disassembly and Replacement: Based on the inspection results, disassemble damaged parts and install new ones, ensuring firm and correct installation. Avoid damaging surrounding parts during disassembly and follow manufacturer specifications for installation.

Lubrication and Adjustment: After replacement or repair, add lubricating oil as needed and adjust the system to ensure all performance indicators meet standards. Lubrication reduces wear during the break-in period of new parts, and adjustment ensures normal suspension system operation.

Testing and Verification: Finally, test the vehicle to verify that all chassis system functions are normal, ensuring repair quality and driving safety. Testing includes actual driving tests and using specialized equipment for inspection.

For a ball joint company or OEM, following these steps ensures high-quality installations and repairs.

The Importance of Ball Joints in the Suspension System

Ball joints play a critical role in the suspension system, which is a core component of the vehicle. The suspension system affects not only driving comfort but also driving safety. The condition of ball joints directly impacts the efficiency and reliability of the suspension system.

Components of the Suspension System

The suspension system primarily consists of springs, shock absorbers, and control arms, with ball joints being crucial connectors between control arms and wheels. The main function of the suspension system is to absorb road impacts, maintaining wheel-to-ground contact for a smooth driving experience.

Role of Ball Joints in the Suspension System

Ball joints allow the suspension system to move freely in vertical and horizontal directions, absorbing road shocks and impacts. This design improves vehicle comfort and ensures stability during steering. Ball joints help maintain correct wheel alignment by allowing suspension system movement in all directions, preventing wheels from deviating from the track. A reliable ball joint manufacturer or ball joint supplier ensures these components meet stringent quality standards to perform effectively.

Impact of Ball Joint Damage on the Suspension System

Ball joint damage negatively affects the suspension system in several ways:

Decreased Handling Performance: Damaged ball joints cause the suspension system to lose its flexibility and stability, affecting vehicle handling performance. During steering, the vehicle may become sluggish or unstable, increasing driving difficulty and danger.

Reduced Comfort: Damaged ball joints affect the suspension system’s shock absorption, making the vehicle bumpier during driving, reducing passenger comfort.

Increased Safety Hazards: Damaged ball joints can lead to suspension system failure, affecting wheel alignment and steering control, increasing safety hazards. At high speeds, ball joint damage can cause severe traffic accidents.

A ball joint OEM or ball joint company must address these issues to maintain the safety and reliability of their products.

How to Extend the Life of Ball Joints

To extend the life of ball joints, besides regular inspection and maintenance, the following measures can be taken:

Pay Attention to Driving Habits: Avoid frequent sharp turns, sudden stops, and fast driving over potholes, as these behaviors increase ball joint load and wear.

Keep the Vehicle Clean: Regularly clean the vehicle chassis, especially after rain or snow, to prevent salt and dirt accumulation around ball joints, causing corrosion and wear.

Use High-Quality Lubricating Oil: Choose high-quality lubricating oil or grease to better protect ball joints, reducing friction and wear.

Timely Replacement of Damaged Parts: Replace damaged ball joints or other suspension system components promptly to prevent small problems from causing major failures.

Professional Maintenance: Regularly take the vehicle to a professional service station for comprehensive inspection and maintenance, ensuring ball joints and suspension system components are in optimal condition.

By implementing these measures, a ball joint manufacturer, ball joint OEM, or ball joint supplier can significantly enhance the durability and performance of their products.

Conclusion

As critical components of the vehicle’s chassis system, ball joints ensure steering flexibility and suspension stability while guaranteeing driving safety. Damaged ball joints directly impact vehicle handling, comfort, and safety, making regular inspection and maintenance essential.

By understanding the function and symptoms of ball joint damage, vehicle owners can better monitor the vehicle’s condition, promptly identify and address potential issues, extend the ball joint’s lifespan, and enhance driving safety and comfort.

During chassis system maintenance and repair, thorough inspection and recording of component status, appropriate disassembly and replacement, lubrication and adjustment, and testing and verification ensure repair quality and driving safety. These steps ensure the vehicle provides optimal performance and safety under all conditions.

A ball joint company, ball joint OEM, or ball joint supplier can benefit significantly from adhering to these guidelines, ensuring their products meet the highest standards of safety and reliability.

Juye is a leading manufacturer of steering system components, renowned for innovation and quality. With over 20 years experience and certifications like ISO9000 and IATF16949, We offer efficient production, technical excellence, and eco-friendly practices. Our goal is to provide tailored solutions for Automobile steering and transmission, enhance user experience, and contribute to sustainable development. Contact us now!

Leave a Reply