“Enhancing Vehicle Performance: A Comprehensive Guide to Control Arms, Tie Rods, and Sway Bars”

In enhancing vehicle performance, modifying and optimizing the suspension system is crucial. Components like control arms, tie rods, and sway bars play a significant role in a vehicle’s stability and handling characteristics. This article will delve into these three essential suspension components, exploring their functions, design, materials, and how modifications can improve vehicle performance.

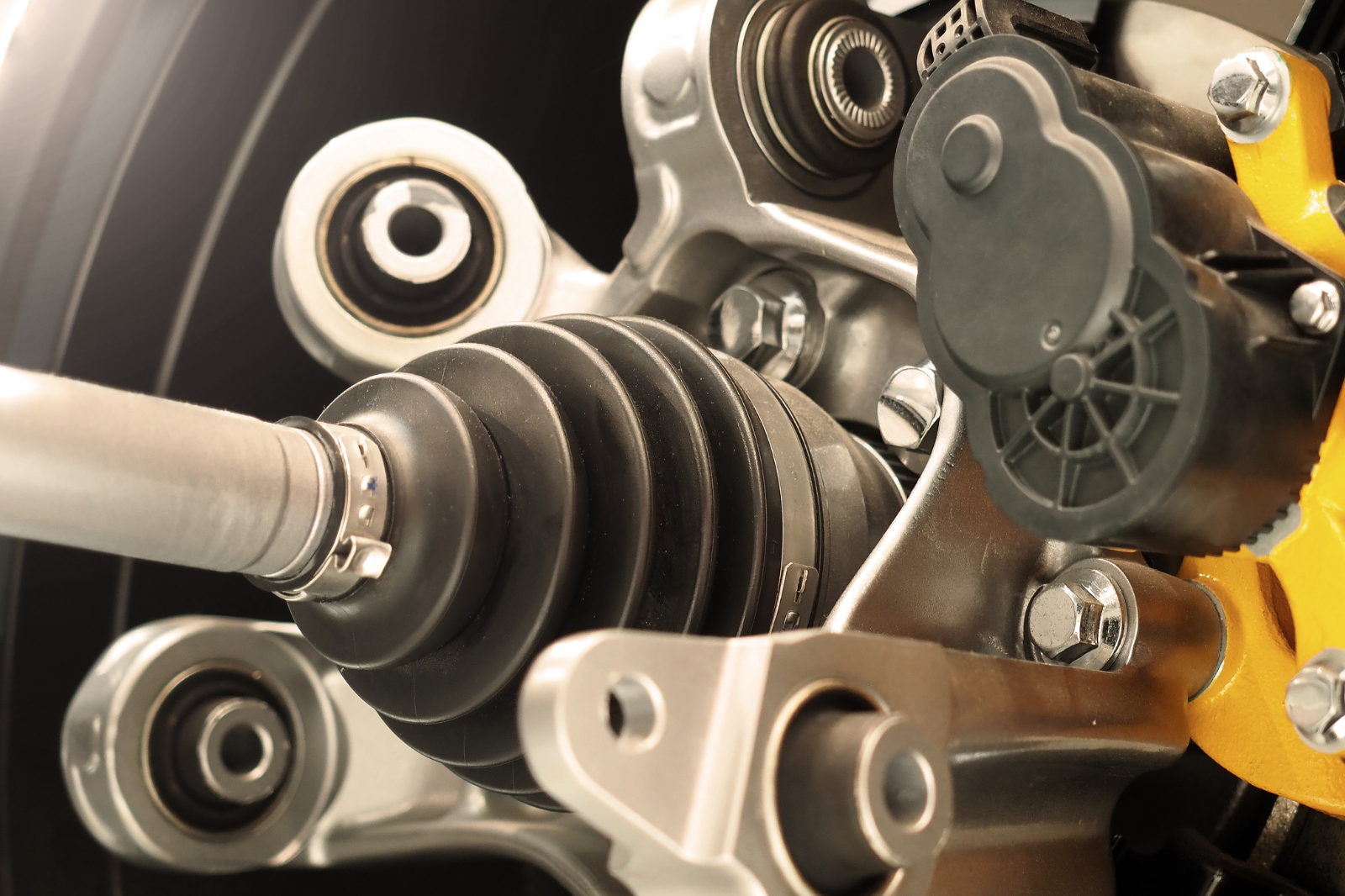

I. Functions and Design of Control Arms

1. Basic Functions of Control Arms

Control arms are pivotal parts of a suspension system, connecting the vehicle’s body to the wheels and transmitting road feedback forces. They facilitate the transfer of impacts from the road to the vehicle’s structure, helping the suspension system absorb shocks more effectively. This enhances the vehicle’s stability and steering precision by maintaining proper alignment and minimizing changes in the wheel’s position during driving.

2. Types of Control Arms

Control arms come in various types, each serving specific functions:

- Upper and Lower Arms: Commonly found in suspension systems, these control arms support the wheels and manage vertical movement.

- Camber Adjusters: These are used to adjust the camber angle of the wheels, ensuring proper alignment to optimize handling and tire wear.

- Linkage Arms: Also known as “Pillow Balls” or “Ball Joints,” these adjustable arms connect sway bars and shocks or lower arms, helping to control body roll and improve handling.

3. Design and Materials of Control Arms

The design of control arms must ensure adequate rigidity and strength to support the wheels and absorb impacts. Material choice is crucial:

- Steel: Steel is commonly used for control arms due to its high strength and durability. Steel control arms are often designed to be robust and able to withstand significant stress.

- Aluminum: Aluminum offers the advantage of weight reduction, which can enhance acceleration and handling. However, aluminum is generally less strong than steel, so aluminum control arms are typically designed with larger dimensions to compensate. The cost of aluminum components is higher due to design and material expenses.

4. Practical Examples

In high-performance or modified vehicles, upgrading control arms can significantly improve handling. For instance, replacing standard control arms with high-strength versions can reduce body flex during high-speed maneuvers, enhancing stability and steering accuracy. Adjustable control arms allow for customization of suspension geometry, optimizing performance for specific driving conditions.

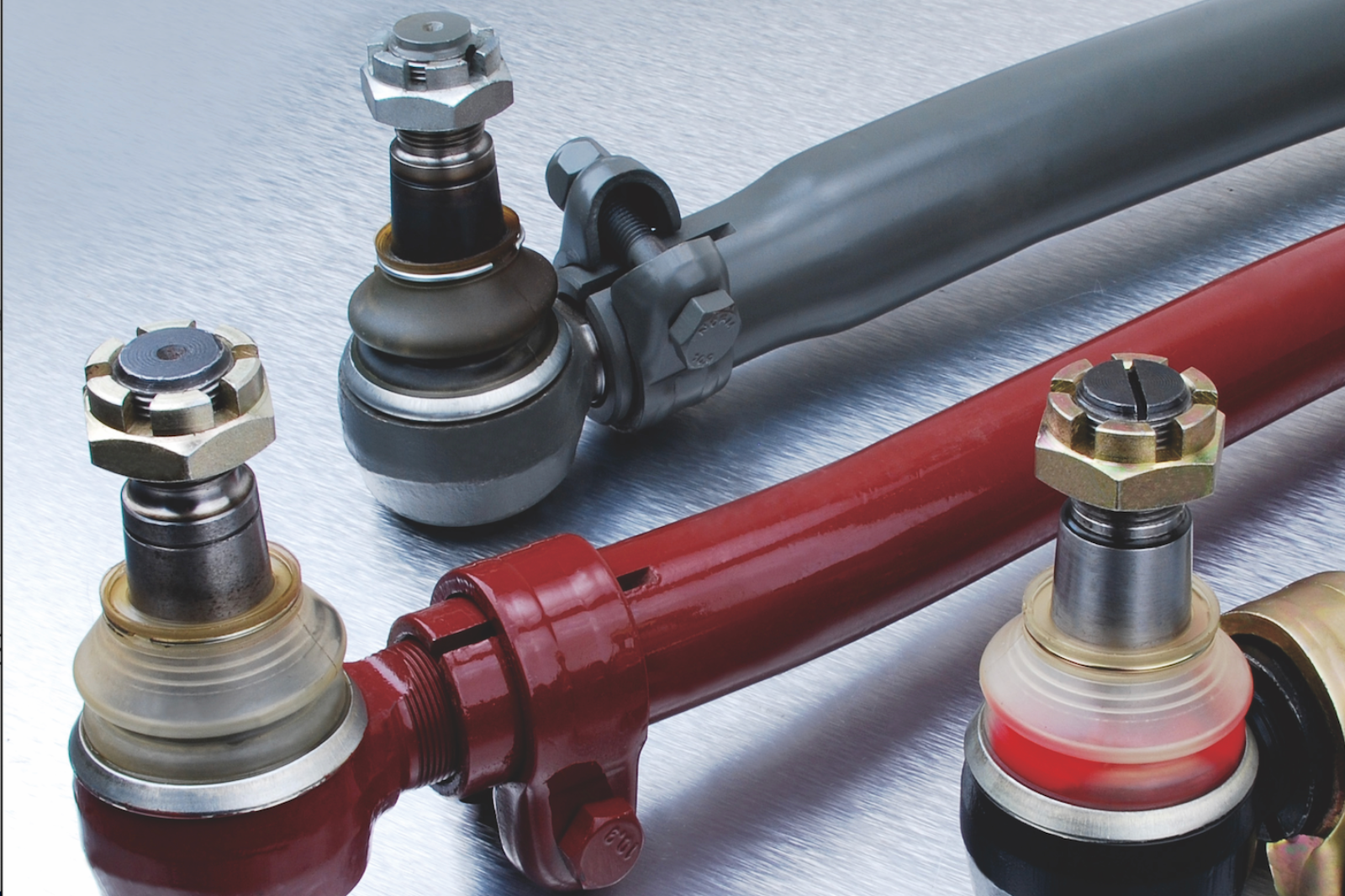

II. Functions and Design of Tie Rods

1. Basic Functions of Tie Rods

Tie rods are designed to increase the rigidity of the vehicle’s body and minimize flexing. By enhancing body stiffness, tie rods improve handling and stability, especially under high-load conditions such as rapid acceleration or sharp turns.

2. Types of Tie Rods

- Engine Bay Tie Rods: These tie rods reduce distortion in the engine bay and enhance overall vehicle stability by connecting different parts of the engine bay.

- Inner Fender Tie Rods: These are used to support the suspension system and prevent structural damage. They help distribute forces more evenly throughout the vehicle.

- Front and Rear Lower Tie Rods: These rods balance the front and rear axle weight distribution and strengthen the chassis. They are particularly useful in reducing chassis flex during rapid acceleration or rough road conditions.

3. Design and Materials of Tie Rods

Tie rods are generally made from high-strength steel to ensure they can handle significant forces. High-end models may use aluminum for weight savings, though aluminum tie rods are typically larger to compensate for their lower strength.

4. Practical Examples

Upgrading engine bay tie rods can enhance stability during aggressive driving by reducing flex in the engine compartment. Front and rear lower tie rods improve chassis rigidity, especially important during high-speed driving or off-road conditions.

III. Functions and Design of Sway Bars

1. Basic Functions of Sway Bars

Sway bars, or anti-roll bars, are crucial for reducing body roll during cornering. While independent suspension systems offer good handling and comfort, body roll can still be a challenge during aggressive driving. Sway bars connect the left and right wheels, helping to balance body roll and improve overall vehicle stability.

2. Design and Materials of Sway Bars

Sway bars must have strong elasticity and resilience to control body roll effectively. Common materials include:

- Steel: Steel sway bars are known for their high rigidity and durability. They are widely used because they offer reliable performance at a lower cost.

- Aluminum: Aluminum sway bars are lighter, which can further enhance handling. However, they are less strong than steel and often require larger diameters to maintain performance. The higher cost of aluminum parts reflects the increased material and design expenses.

3. Practical Examples

Upgrading to a high-performance sway bar can significantly improve handling by reducing body roll and increasing cornering stability. High-end sway bars are designed with superior materials and engineering to outperform standard components, providing better control and safety during aggressive driving.

IV. Conclusion

Control arms, tie rods, and sway bars are crucial components of a vehicle’s suspension system, each serving distinct roles. Control arms connect the body to the wheels and absorb road impacts, enhancing stability and alignment. Tie rods increase body rigidity and stability, particularly under high-load conditions. Sway bars are essential for controlling body roll during cornering, improving handling and stability.

Understanding these components’ functions and design features allows vehicle owners to make informed decisions about modifications and upgrades. Properly chosen and installed components can significantly enhance a vehicle’s performance, handling, and overall driving experience.

Juye parts brand mission is centered on customers, delivering high-quality accessories and services. We drive better experiences through technological innovation, aiming to create value, foster win-win partnerships, ensure sustainable, low-carbon production, and elevate employee well-being.

Leave a Reply