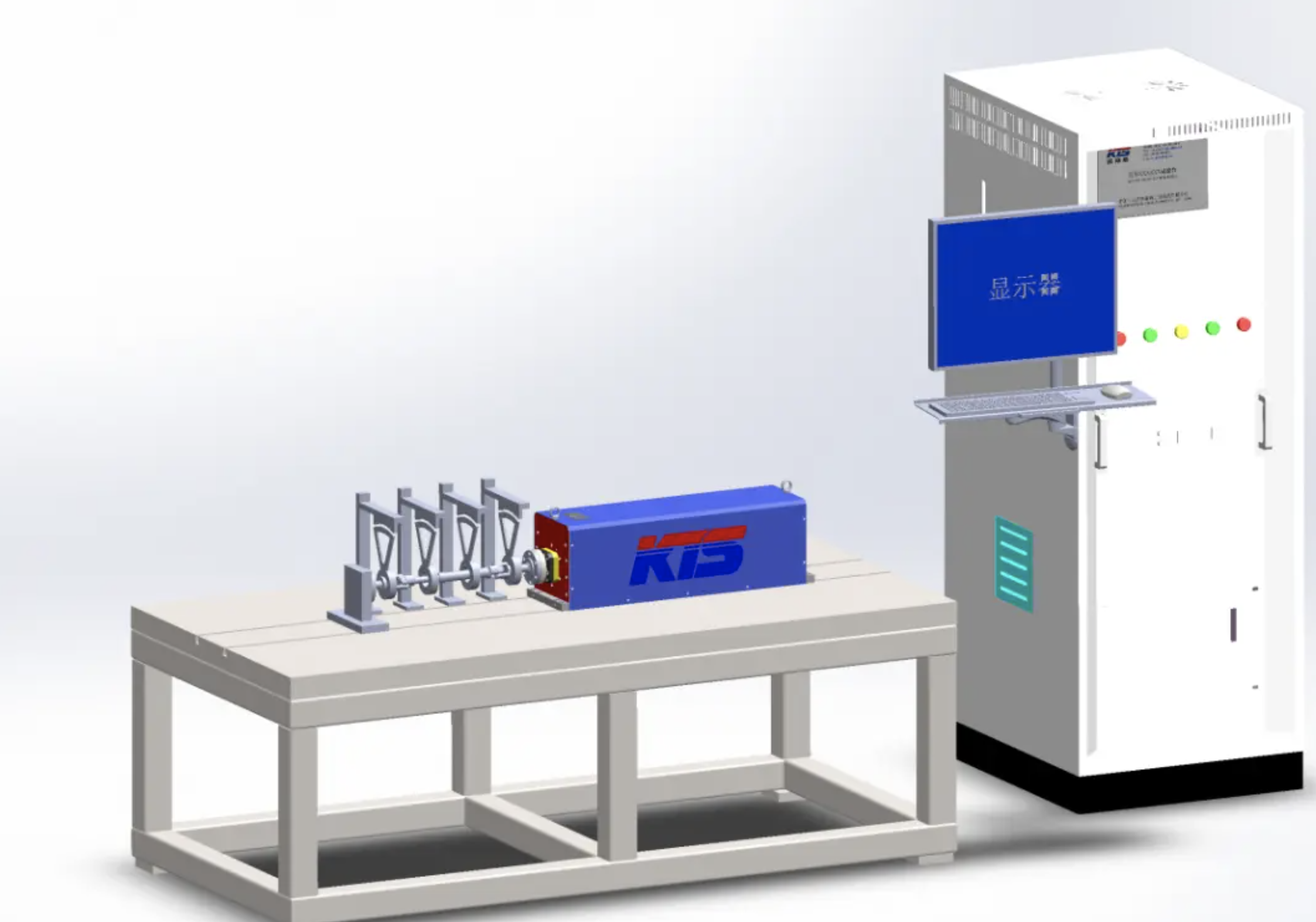

What is the solution for testing the intermediate shaft clearance of the automobile steering drive shaft column?

Testing the intermediate shaft clearance of the automobile steering drive shaft column involves a specific procedure using specialized equipment. Here’s a detailed solution for conducting this test:

1. Scope of Application

This testing solution is designed to measure the clearance of automobile steering shafts. It can clamp the gaps at various parts of the shaft simultaneously and measure them accurately.

2. Experimental Projects

The equipment is used for the following tests:

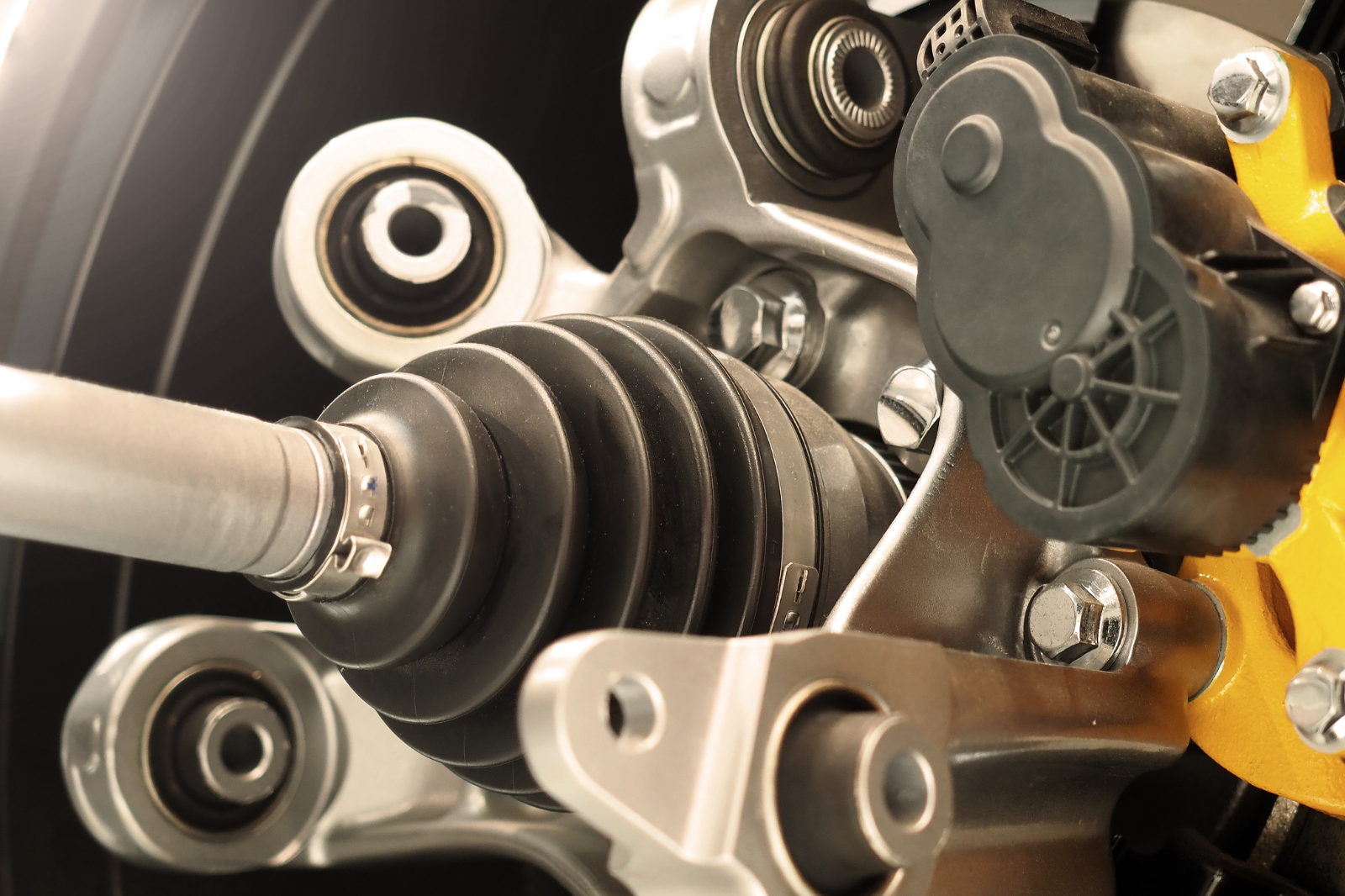

- Intermediate Shaft Assembly Clearance Detection: Measures the clearance within the intermediate shaft assembly.

- Universal Joint Angle Gap Detection: Measures the gap or play within the universal joint at different angles.

- Sliding Parts Angle Gap Detection: Measures the clearance or play in the sliding parts of the steering shaft.

3. Main Working Principles and Functions of the Equipment

The testing equipment typically comprises three main systems:

- Mechanical Bench System: Provides a stable and precise platform to clamp and manipulate the steering shaft components.

- Electrical Control System: Manages the power and electronic controls necessary for the operation of the testing equipment.

- Industrial Control System: Integrates sensors, data acquisition, and control algorithms to monitor and measure the clearances accurately.

Detailed Steps for Testing Intermediate Shaft Clearance

Step 1: Preparation

- Set Up the Mechanical Bench System: Securely mount the intermediate shaft onto the mechanical bench. Ensure that the shaft is properly aligned and clamped at multiple points if necessary.

- Initialize the Electrical Control System: Power on the system and ensure all electronic components are functioning correctly.

Step 2: Intermediate Shaft Assembly Clearance Detection

- Clamp the Shaft: Use the mechanical bench to clamp the intermediate shaft securely.

- Apply Forces: Apply axial and radial forces to simulate operational conditions.

- Measure Clearances: Use sensors to measure the clearances at different points along the intermediate shaft. The data is sent to the industrial control system for analysis.

Step 3: Universal Joint Angle Gap Detection

- Position the Shaft: Adjust the shaft to position the universal joint within the measurement range.

- Rotate and Measure: Rotate the shaft through different angles and measure the gap or play in the universal joint at each angle. This ensures the joint functions correctly under various steering conditions.

Step 4: Sliding Parts Angle Gap Detection

- Extend and Retract the Shaft: Move the sliding parts through their full range of motion.

- Measure Sliding Clearances: Measure the clearance or play at various positions and angles to ensure the sliding parts operate smoothly without excessive play.

Main Equipment Components and Functionality

Mechanical Bench System

- Clamping Mechanisms: Securely hold the steering shaft components in place.

- Force Application Tools: Apply controlled forces to simulate real-world conditions.

Electrical Control System

- Power Supply: Provide consistent power to all electronic components.

- Control Interfaces: Allow operators to input commands and adjust settings.

Industrial Control System

- Sensors: Measure clearances, angles, and forces with high precision.

- Data Acquisition: Collect and store measurement data for analysis.

- Control Algorithms: Process measurement data and provide feedback to ensure accurate and repeatable results.

Conclusion

The solution for testing the intermediate shaft clearance of the automobile steering drive shaft column involves a comprehensive setup that includes mechanical, electrical, and industrial control systems. This setup allows for precise measurement of clearances at various parts of the shaft, ensuring the steering system’s reliability and safety. The testing procedure includes preparation, clamping, applying forces, and measuring clearances at different points and angles, providing a thorough assessment of the shaft’s performance under simulated operating conditions.

With over 20 years experience and certifications like ISO9000 and IATF16949, JUYE offer efficient production, technical excellence, and eco-friendly practices.

Leave a Reply