Introduction to automobile steering knuckle arm

Definition

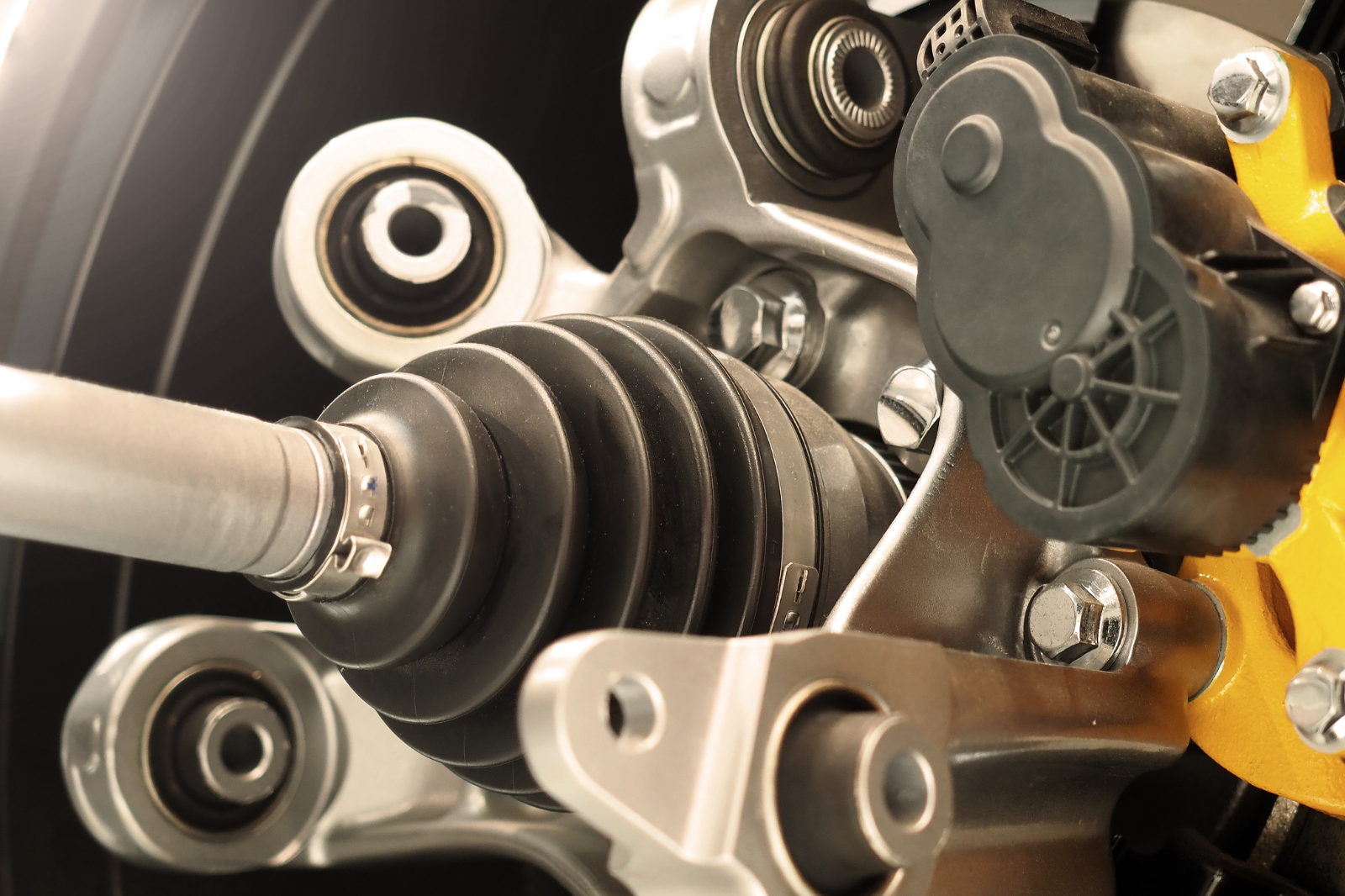

The steering knuckle arm, also known as the trapezoidal arm, is a crucial component in the automobile steering transmission system. It is the final power transmission element in the system. The steering knuckle arm is installed on the left and right steering knuckles, with the other end connected to the tie rod through a ball joint.

Function

During the driving process, the vehicle often needs to change its driving direction (steering). Typically, when the vehicle is turning, the driver applies a steering torque to the steering wheel. This torque is transmitted through the following path:

- Steering Wheel: The force applied by the driver.

- Steering Shaft: Connects the steering wheel to the steering gear.

- Steering Gear: Amplifies the steering torque.

- Pitman Arm: Connects the steering gear to the steering knuckle arm.

- Steering Linkage (Tie Rod): Connects the pitman arm to the steering knuckle.

- Steering Knuckle and Steering Knuckle Arm: The steering knuckle arm transmits the torque to the wheel hub, causing the wheels to turn and complete the steering operation.

The steering knuckle arm needs to have the functionality to connect the tie rod and the wheel hub and enable steering.

Key Points to Note When Assembling the Steering Knuckle Arm

Connection Method:

- The steering knuckle arm is connected to the steering knuckle mainly through a 1/8 to 1/10 taper and splines. This connection is firm and not prone to loosening, although the machining process of the steering knuckle is relatively complex.

Material and Heat Treatment:

- The steering knuckle arm is usually forged from the same material as the steering knuckle and is heat-treated to achieve the same hardness. Appropriate hardness can increase the fatigue life of the part, but if the hardness is too high, the toughness of the part will be poor, and machining will be difficult.

Assembly Clearance and Lubrication:

- Fit Clearance: The allowable fit clearance for the steering knuckle arm or bushing is 0.3 to 0.5 millimeters. If there is excessive wear, it should be replaced.

- Lubrication: During assembly, the bushing should be oiled, and lithium-based grease should be filled between the two bushings.

Nut Adjustment:

- After tightening the adjustment nut, the steering knuckle arm should not turn due to its own weight when in a horizontal position, but should be able to turn when a force of 1-2 kilograms is applied to the end of the steering knuckle arm. If the nut is too tight, it should be loosened, the washer lifted, and the bolt retightened.

Following these steps and considerations ensures the correct assembly and proper functioning of the steering knuckle arm, thereby guaranteeing the stability and reliability of the automobile steering system.

Juye parts brand mission is centered on customers, delivering high-quality accessories and services. We drive better experiences through technological innovation, aiming to create value, foster win-win partnerships, ensure sustainable, low-carbon production, and elevate employee well-being.

Leave a Reply