Innovating Automotive Parts Through Rigorous Testing and Development

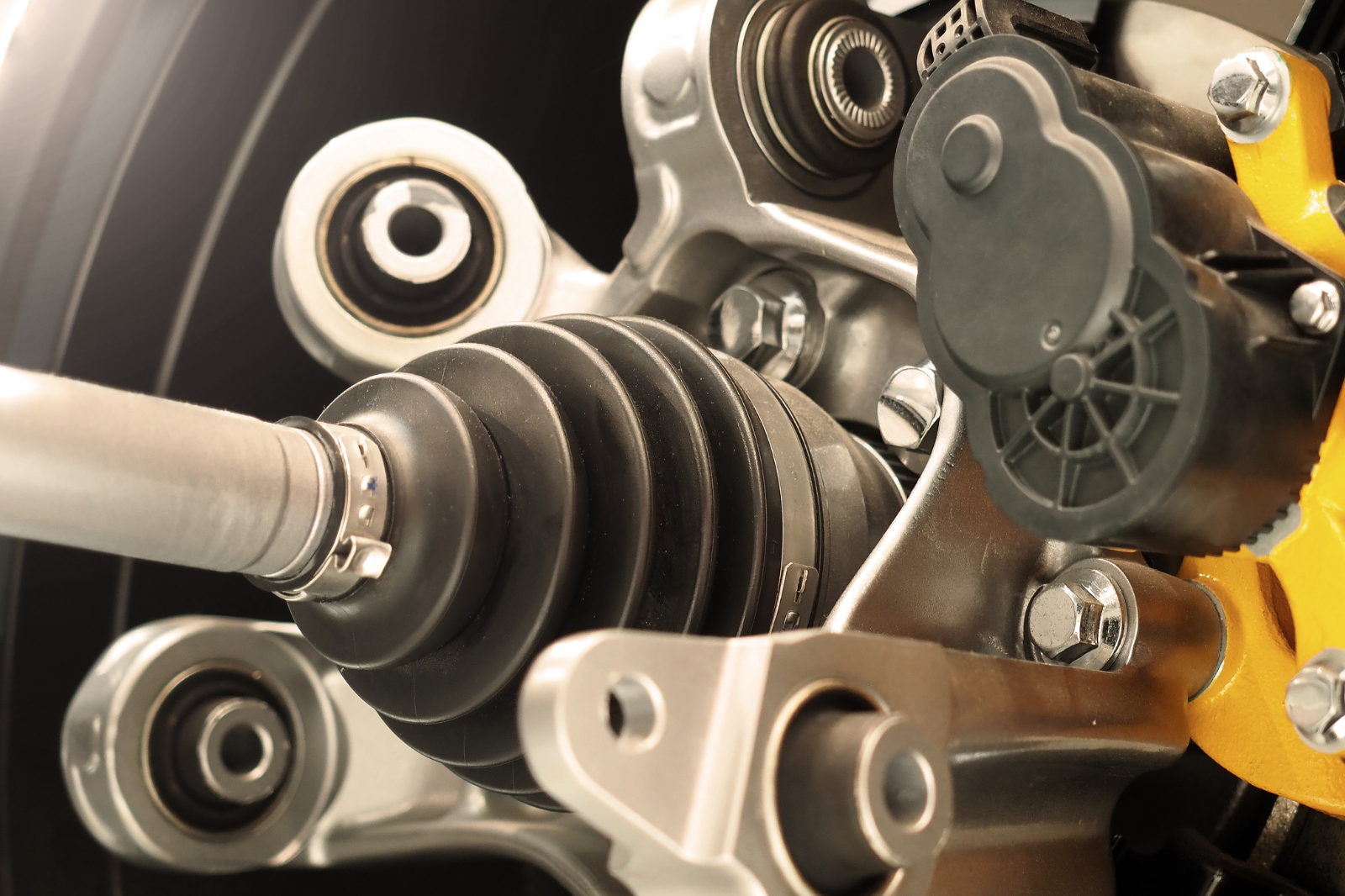

JUYE, recognized as “The Problem Solver,” excels in creating innovative solutions for automotive parts, particularly focusing on steering and suspension. Their commitment to product improvement is evident in their approach to enhancing both individual components and the entire product development process. This commitment is particularly showcased in their methodical testing of dust boots, crucial for the longevity and reliability of their products.

Detailed Testing Conditions Established by JUYE:

- Swing Angle Testing: The swing angle is crucial, tested at 80% of the product design specification (0 to ±25º). This ensures dust boots maintain performance under various swinging scenarios.

- Swing Frequency Range: Set between 1 to 3 Hertz to mimic normal driving vibrations, with a maximum of 8 Hertz for extreme conditions.

- Rotation Angle Testing: Rotation angle is set to 80% of the wheel turning angle design (0 to ±40º), simulating maximum turning angles encountered in driving.

- Rotation Frequency Range: Ranges from 0.3 to 1 Hertz, extendable up to 6 Hertz, ensuring performance at different speeds.

- Load Direction Setting: Load direction in tests follows specific diagrams for accuracy and relevance.

- Load Application: Simulates actual loads perpendicular and along the axis, with perpendicular load at half the designed front axle load.

- Load Frequency: Ranges from 0.1 to 1 Hertz to simulate dynamic load changes under various driving conditions.

- Number of Test Cycles: Swing cycles in the test are set at one million or adjusted as per customer requirements.

- Mud and Water Flow Simulation: Simulates muddy water conditions (0.5 to 3 liters per minute) to test part durability and protection under harsh road conditions.

Through these comprehensive tests, JUYE ensures optimal performance of key components like dust boots in extreme environments and under varied driving conditions.

Importance of Testing in Product Development: Testing is fundamental to JUYE’s strategy for high-quality steering and suspension parts. Rigorous testing of each part before market release ensures they meet or exceed Original Equipment (OE) specifications, helping to identify and rectify design weaknesses and enhance performance.

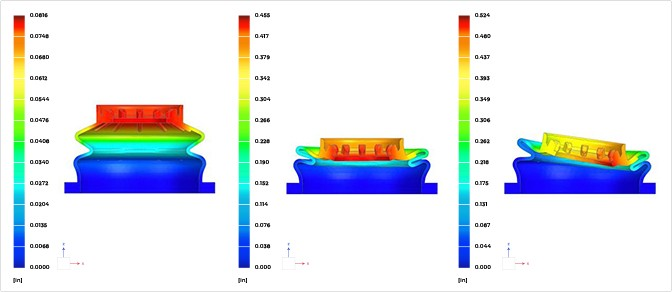

Computer Simulation for Optimization: JUYE uses computer simulations to optimize stress distribution across the part’s movement range before physical testing, enhancing the durability of their dust boots.

Custom Solutions for Unique Challenges: JUYE developed proprietary testing equipment for dust boots, addressing the lack of suitable commercial testers. This equipment tests endurance under extreme temperatures and environmental conditions, mimicking ball joint motion.

Rigorous and Extensive Testing Regime: The boot tester is designed for harsh road demands, checking performance in extreme temperatures and resistance to tears, holes, and degradation from various substances.

Comprehensive Testing for Superior Quality: JUYE’s extensive testing results in durable dust boots that withstand real-world conditions, playing a vital role in protecting socket components and extending part lifespan.

By integrating detailed testing conditions like specific swing and rotation angles, frequencies, load directions, and environmental simulations, JUYE demonstrates its dedication to delivering premium, reliable, and durable chassis parts, ensuring customer satisfaction and brand trust.

Leave a Reply