Embracing Automotive Industry 4.0: JUYE Innovative Path

The automotive sector is witnessing a revolutionary shift with the advent of Automotive Industry 4.0, a change JUYE is actively embracing. This era is marked by the fusion of advanced digital technologies across the automotive value chain, a movement JUYE is not just following but leading.

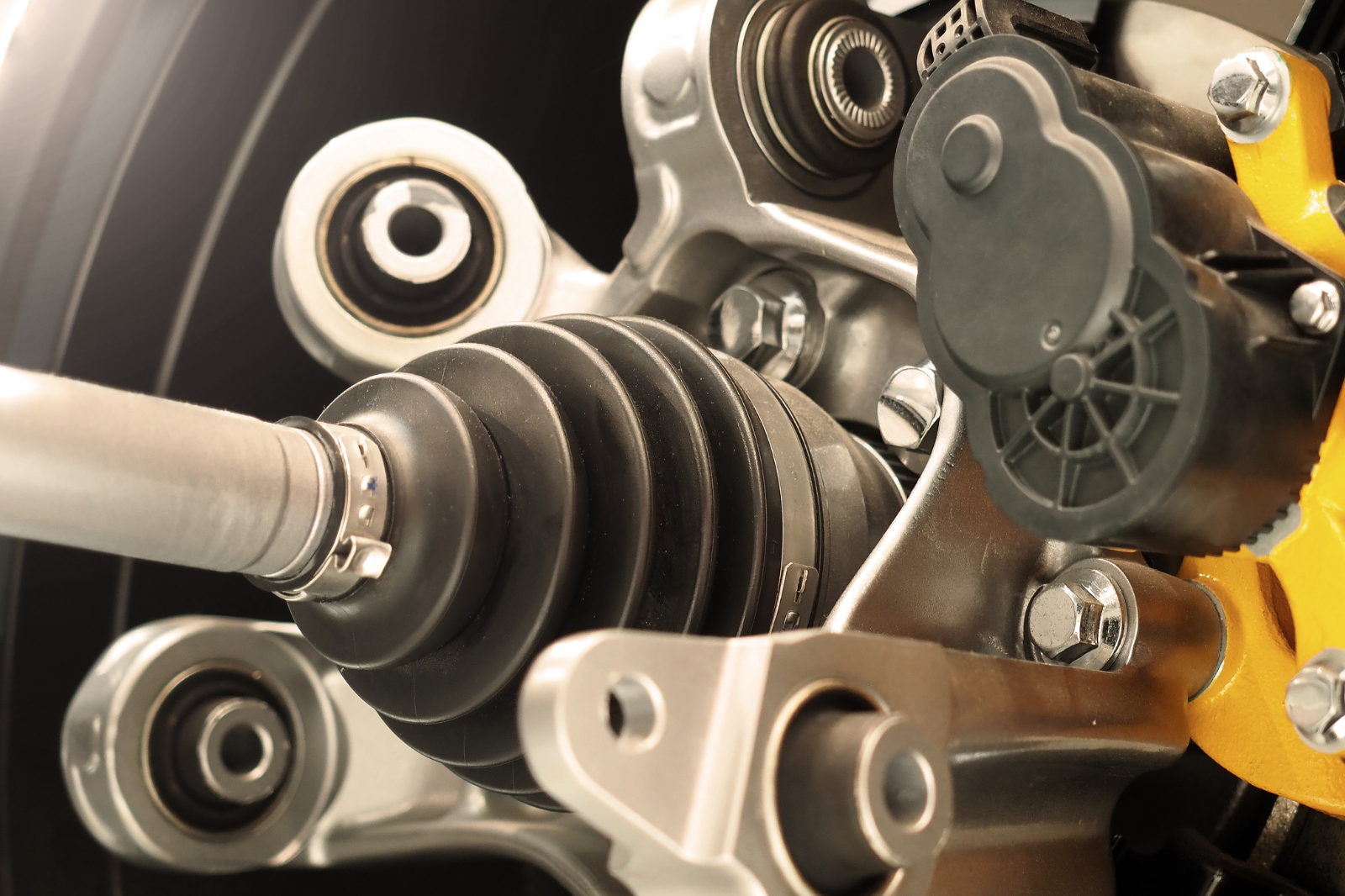

Innovation and Automation for Process Excellence

JUYE is channeling investments into state-of-the-art technologies to revolutionize their production processes, aiming for peak efficiency. For instance, the integration of automation and collaborative robotics on assembly lines is a game-changer. This shift allows for heightened precision and expedited production of components and vehicles. An illustrative example is the robotic arm JUYE recently implemented, which can assemble parts with a precision of 0.01mm, significantly enhancing product quality. Furthermore, the adoption of sensors and intelligent control systems offers real-time monitoring, boosting quality assurance and slashing production times.

Data Analysis and Big Data: The New Frontier

Another strategic move by JUYE is leveraging data analysis and Big Data. By mining the vast data pools generated by sensors and connected systems, JUYE gains critical insights into product performance and process efficiency. This approach facilitates informed decision-making, early fault detection, and supply chain optimization. For example, their new data analytics platform has led to a 15% reduction in component failure rates, showcasing the power of data in operational excellence.

Collaboration and Adaptation in the Industry 4.0 Ecosystem

Recognizing that transitioning to Automotive Industry 4.0 demands collaborative efforts, JUYE is building bridges with various stakeholders in the supply chain. Integrating systems and ensuring seamless communication between manufacturers, suppliers, and distributors is crucial for thriving in this new digital age. Additionally, JUYE’s agility in adapting to novel business models and evolving market demands positions them as a leader in this space. A testament to this is their recent partnership with a leading software company to develop a shared logistics platform, reducing supply chain inefficiencies by 20%.

Conclusion: Leading the Digital Charge

In conclusion, JUYE is not just adapting but excelling in the transition to Automotive Industry 4.0. By harnessing advanced technologies, leveraging data analytics, and fostering strategic collaborations, JUYE stays ahead in the industry, ensuring they deliver top-notch products and services in this new, digital-first world.

Leave a Reply