Analysis of Loose Steering Rod

The issue of looseness in a truck’s steering tie rod can significantly impact the vehicle’s handling stability and safety. Analyzing this problem involves several aspects, and here are some potential causes for looseness in the steering tie rod:

Wear and Tear: Wear of the tie rod and its ends is the most common cause. Over time, these components can gradually wear out due to friction and pressure.

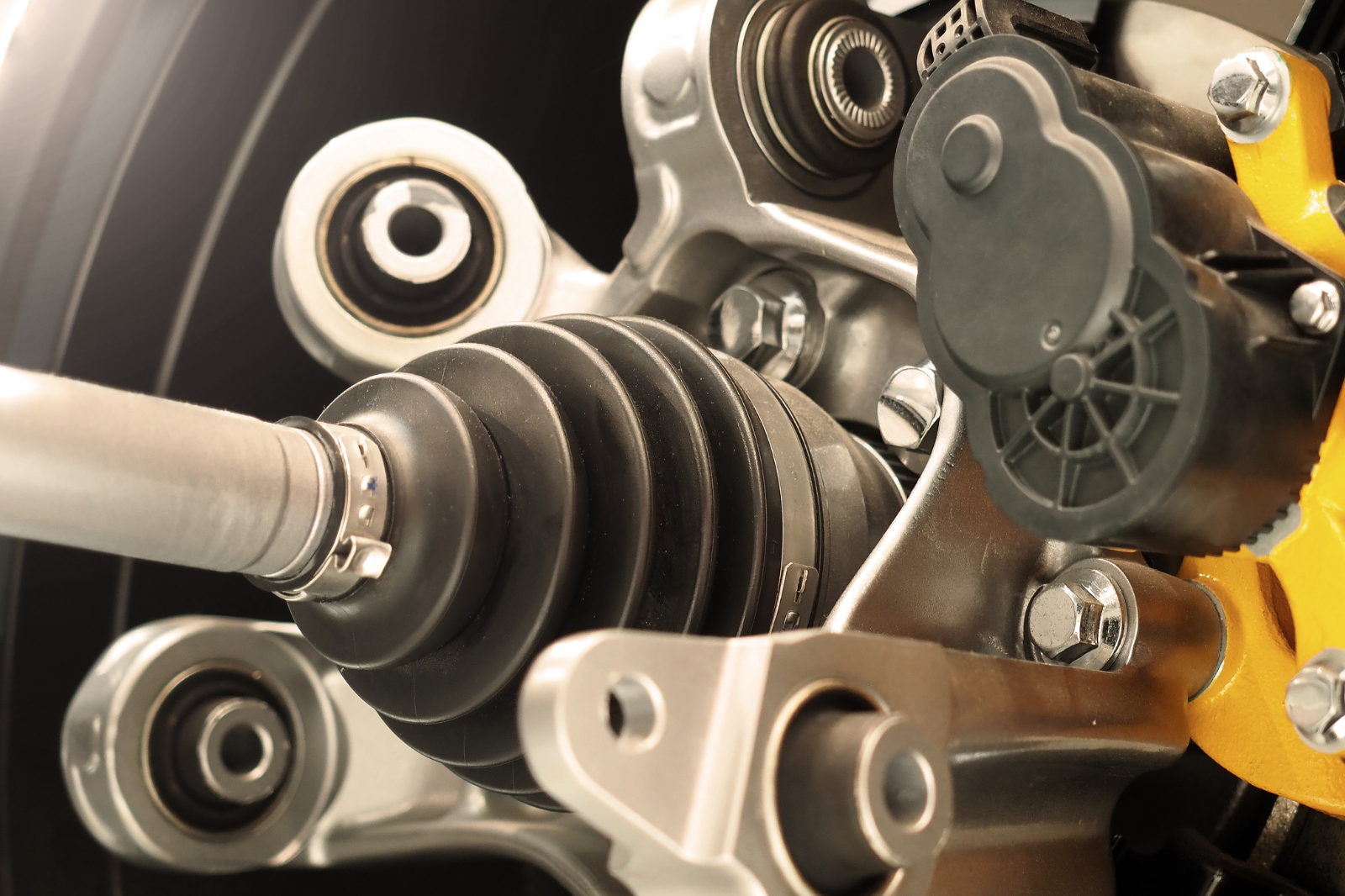

Damaged Ball Joints: If the ball joints at the ends of the tie rod are damaged or worn, it can lead to looseness. Ball joints are crucial movable parts in the steering system and can be damaged due to collisions or long-term wear.

Loose Fasteners: If the bolts or nuts securing the tie rod are loose, this can also result in looseness. This might be due to vibration, improper installation, or thread wear.

Insufficient Lubrication: If the tie rod and its ends are not properly lubricated, it could accelerate wear and lead to looseness.

Collisions or Overuse: Major collisions or prolonged use in harsh road conditions can also cause damage or looseness in steering system components, including the tie rod.

Manufacturing or Installation Defects: Manufacturing defects or errors during installation can also lead to looseness in the tie rod.

To address such issues, the following steps are typically necessary:

Inspection: Conduct a thorough inspection of the tie rod and related components to identify the exact location and cause of the looseness.

Adjustment or Replacement: Depending on the inspection results, it may be necessary to adjust fasteners, lubricate components, or replace worn parts.

Professional Repair: For issues with the steering system, it is advisable to have the inspection and repair carried out by professional technicians to ensure vehicle safety.

Note that regular vehicle maintenance and inspection can prevent such problems, ensuring the safe operation of the vehicle.

Leave a Reply