Driving Innovation: The Evolution of Lightweight Automotive Materials

The automotive industry has witnessed significant growth over the past two decades. While it has matured in Europe and North America, emerging markets like India and South Korea are still experiencing expansion. Remarkably, in 2021, China became the leading producer of passenger vehicles globally, with an estimated 21 million units. This surge in vehicle production is driving the demand for automotive suspension components.

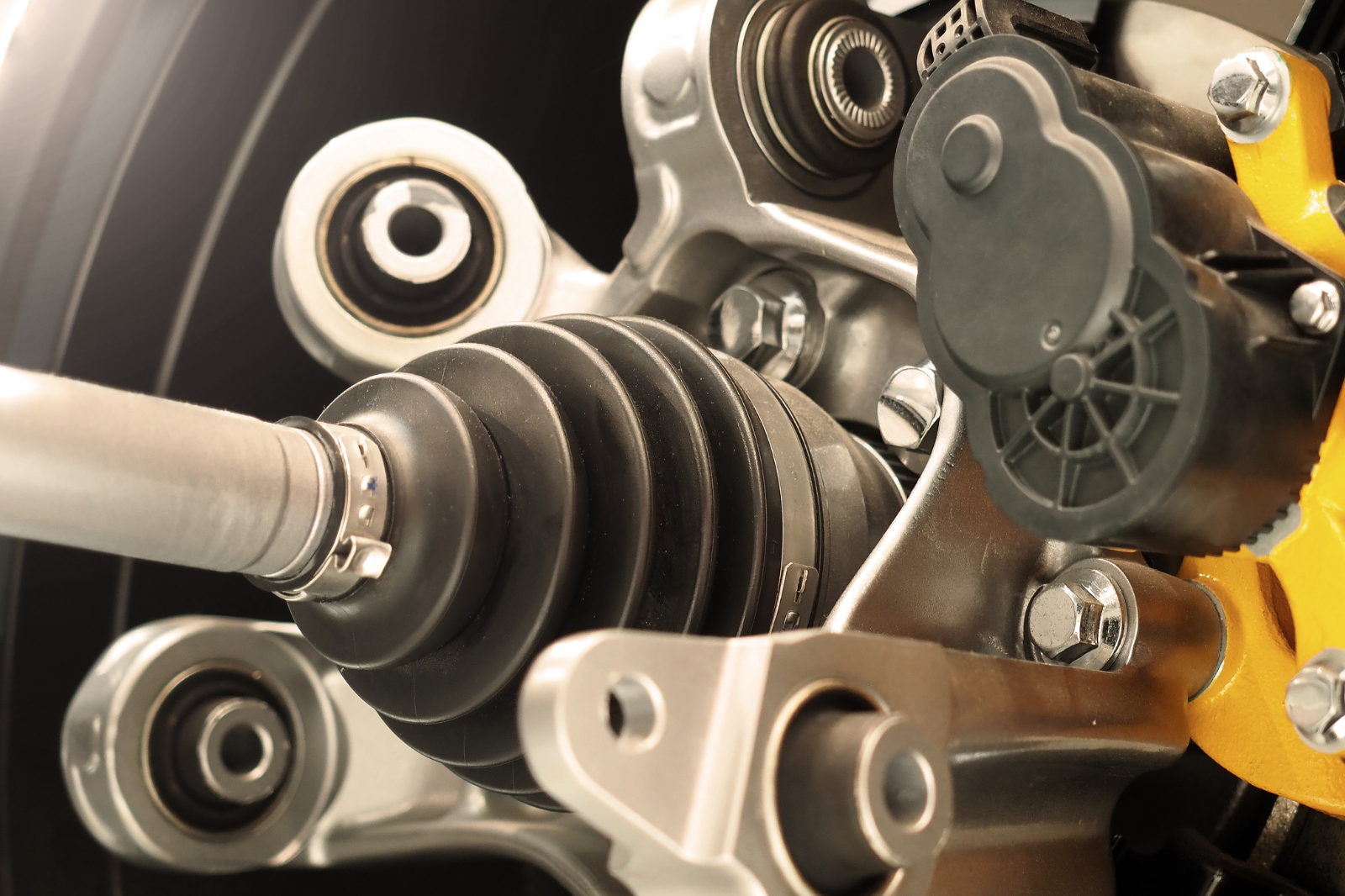

Automotive suspension parts are commonly manufactured through hot forging. This process yields intricate shapes with precise tolerances, making it a competitive choice, particularly for lightweight car suspension parts. Some components can be crafted with ingot surfaces, enhancing efficiency.

In line with an embodiment of innovation, an integrated shock absorber assembly 20 features sensor technology 38. The sensor employs a Hall effect sensor comprising a strip magnet 86 with aligned north and south poles. It is affixed to a metal strip 88, which is securely attached to the shock body 26. This metal strip serves as a protective shield, safeguarding the magnetic strip 86 from harsh environmental conditions.

Semi-active shock absorbers are regulated by a control system comprising circuit boards, A/D/A converters, and memory chips. This system determines the damping level of the shock absorber assembly 20, which varies based on fluid flow. Depending on the control system type, damping levels can be adjusted on a millisecond basis. Another approach is frequency-dependent damping, which is eco-friendly and temperature-stable as it doesn’t rely on oil.

An additional technique is Micro-Amplitude Damping (MAD), utilizing a position-sensitive hydraulic circuit to respond to shock absorber displacement. Lightweight materials for automotive suspension parts encompass various materials, aiding in vehicle weight reduction. This includes composites composed of epoxy resin and vinylester resin with steel inserts, offering weight reductions of up to 35%, ideal for high-volume production.

The growth of the automotive lightweight materials market is anticipated to accelerate in the coming years as manufacturers seek to reduce vehicle weight and enhance fuel efficiency. Factors propelling this market include stringent vehicle emission regulations and government initiatives to curb CO2 emissions.

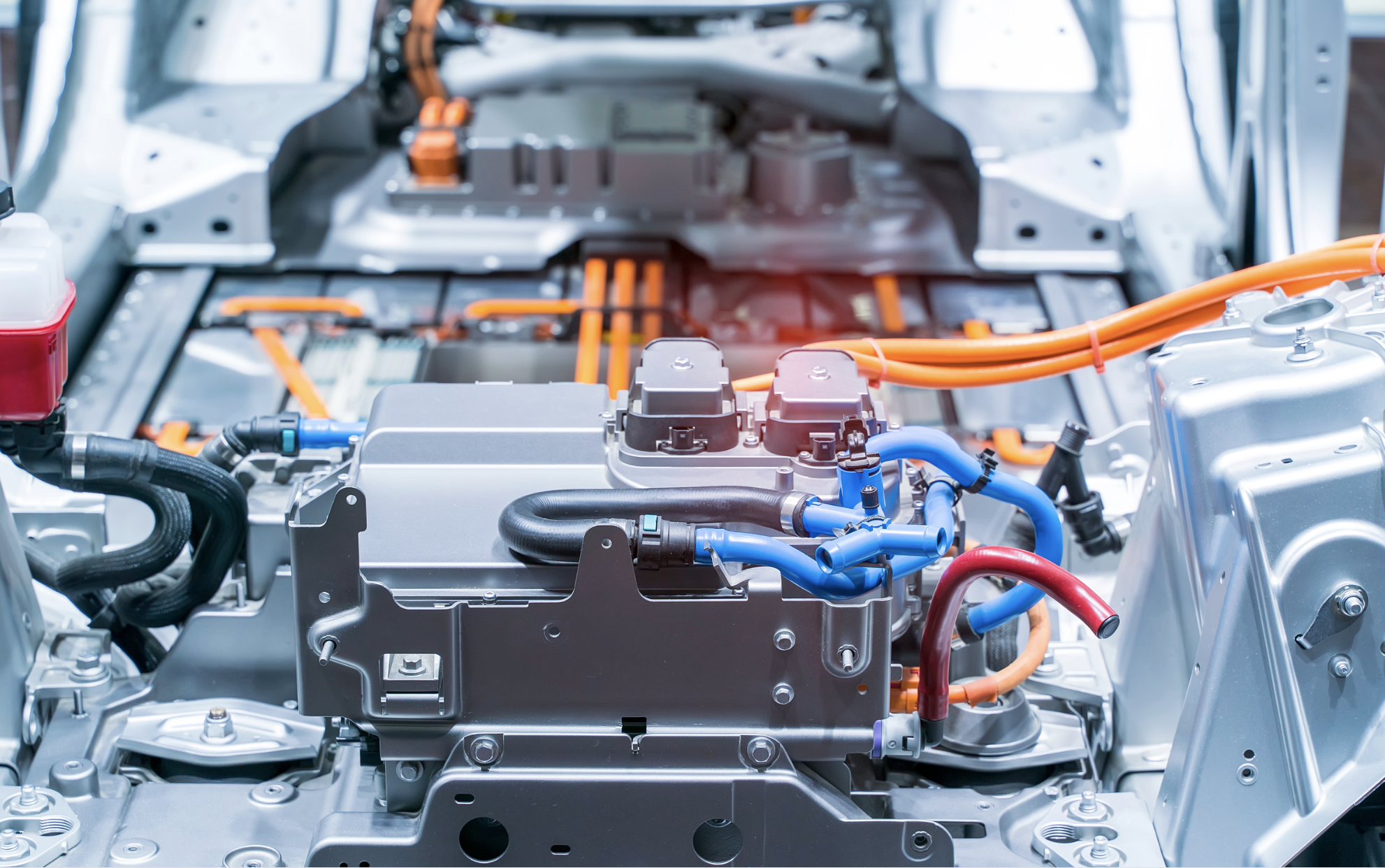

The rising popularity of electric vehicles will further stimulate the demand for automotive lightweight materials. Estimates suggest that electric vehicle sales will rise significantly in the coming years. As the automotive lightweight materials market expands, manufacturers will need to increase production to meet evolving vehicle regulations and market demands.

Leave a Reply